Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

Indirect Procurement — What You Should Know?

Key takeaways

- Indirect procurement refers to the acquisition of goods and services essential for daily business operations, but not directly used in production.

- Examples include hiring professionals like lawyers or marketing experts, managing facilities, organizing travel, and other non-product-related expenses.

- Optimizing indirect procurement can lead to cost savings and improved overall efficiency.

The concept of indirect procurement may seem basic to the seasoned procurement manager, but it is a concept that also needs studying and clarification. Because it is a term that is encountered often, there will be times when it is misunderstood.

In this article, we are going to discuss what indirect procurement is. We will tackle its importance and its difference with direct procurement. Also, we are going to show you some examples of direct procurement and the metrics you can apply for indirect procurement strategy. Furthermore, we are going to discuss the challenges and best practices of indirect procurement.

Once you finished reading this article, you should be a master of this procurement process with the tools and knowledge on how to apply the process successfully.

What is Indirect Procurement?

Indirect procurement refers to goods or services that are not directly used in making products. To put it simply, it is the act of buying or procuring materials or supplies to keep the daily operations of your business alive.

Procurement managers, in charge of indirect procurement, work with suppliers and talk to others in the company to buy the necessary materials. They also keep an eye on spending.

The costs of indirect procurement-related materials or services have gone up. This made companies pay more attention to making indirect spending better. They want to make sure they use money wisely.

To improve indirect procurement in your company, you need to understand what suppliers need. To save money, your company should always check how it spends money and find better ways to work with suppliers.

The Importance of Indirect Procurement

Indirect procurement is important because it helps a company run smoothly. It’s about buying things that aren’t directly used to make products, like office supplies, computers, or services. Even though it’s not the main spending, it still matters a lot.

When a company gets more efficient in how it buys these indirect materials or services, it can save money and work better. For example, if a company gets good deals on office supplies or hires experts at a good price, it can use its money wisely.

Thus, it might not be the biggest part of spending, but making it better can help a company do well by saving money and making things run nicely.

The Differences Between Direct Procurement and Indirect Procurement

The following are the main differences between direct and indirect procurement:

Examples of Indirect Procurement

Examples of indirect procurement include getting help from professionals like lawyers, marketing experts, or IT advisors. It also covers things like taking care of buildings, organizing travel, and other costs that aren’t directly connected to making products.

Unlike buying actual things, like materials for products, it is about getting services or intangible resources. This needs extra thought to make sure it’s worth the money.

Here’s what happens: People look at what the company spends money on and talk to the people who sell those services. They try to get the best deal, like paying less for good legal advice or finding a good deal on travel.

Also, they need to maintain good relationships with the people who provide these services and talk to other employees in the company to find ways to save money. And it’s smart for companies to have a clear plan for how they spend money this way so that everyone will follow the rules strictly.

Metrics You Can ApplyFor Your Indirect Procurement Strategy

Because indirect procurement is crucial for a company’s stability, it requires a well-thought-out plan. This plan ensures that the things bought are good quality, reasonably priced, and meet the company’s set standards.

The job of creating, carrying out, and sticking to this indirect procurement plan falls on the procurement manager. A strong plan typically includes the following metrics or standards:

1. Automation

Again, e-procurement is key to achieving good procurement results. Process automation through e-procurement solutions is becoming more and more popular nowadays because it simplifies the entire procurement process.

From gathering data to comparing vendors, a procurement strategy has never been easier. Of course, the said strategy should still have its human touch and it’s the job of the procurement manager to do that part.

2. Innovation

Suppliers should also be involved in the procurement strategy as they are well-versed with innovation. Suppliers must work together with the internal procurement team to come up with innovations that will help the strategy as a whole.

3. Value Creation

For the procurement manager, creating value for the stakeholders is still the top priority. This means finding ways to get the best deals and use the company’s money wisely when purchasing things that aren’t directly used in making products.

4. Cost Control

For a great strategy to work, there should be cost control. It will remain as main goal of the procurement team. This is probably the only area where both indirect and direct procurement meet in the middle.

The methods used for achieving this are supplier negotiations, pooling of purchases, specification of adjustments, and even the change of suppliers.

5. Responsible procurement

Finally, companies that deal with procurement must make it mandatory to practice Corporate Social Responsibility or CSR.

What this means is that the procurement team makes it a point to check their supplies and whether services or products are acquired through ethical and responsible means. While it is not yet popular among huge companies, the idea is catching on rather quickly.

Challengesof Indirect Procurement

Here are some of the possible challenges that you can face in indirect procurement:

1. Handling a Lot

In the world of procurement, there’s usually a lot going on at the same time. This includes working on big deals with many suppliers while keeping an eye on different things we spend money on. Handling all of this can be quite complicated and needs good planning to use time and money well.

2. Not Always Clear

Sometimes, the people who need to say “yes” to purchases don’t know about them right from the start, or they’re not kept in the loop as things progress. This can slow things down. Thus, it can also lead to missing important information.

3. Control

Imagine you’re the captain of a ship, but you can’t see the whole sea. When different people ask for things and different people approve them, it’s hard to see where the money is going. It’s like not being able to see all the spots on a map. Having smoother processes is like having a clearer map – it helps you see what’s happening and keeps things in order.

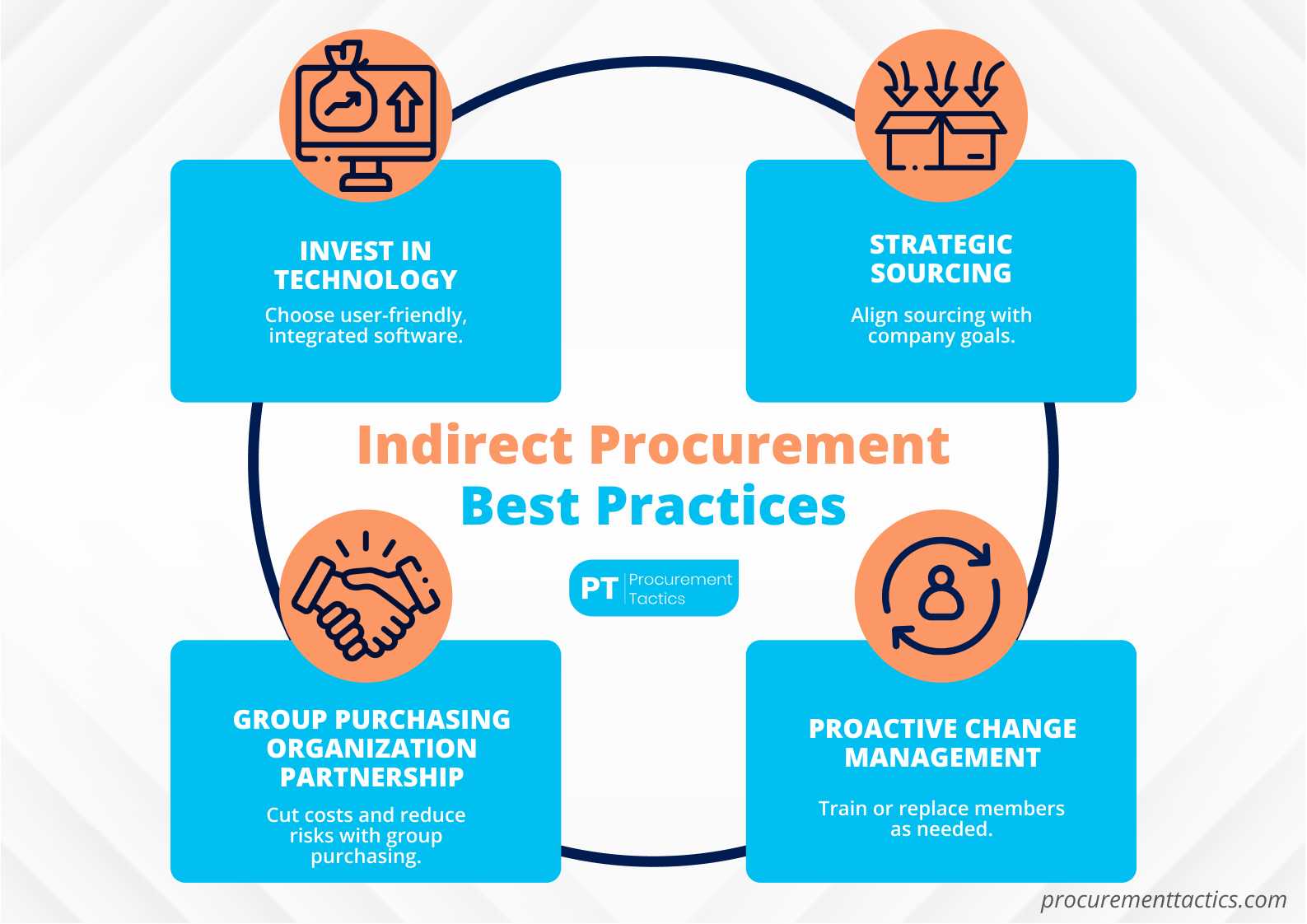

The Best Practicesof Indirect Procurement

Now, let’s discuss the best practices that a procurement manager can use during the procurement process.

These practices are like secret tricks that can help the company’s procurement team excel in following the strategy they’ve set. Here are some best practices to keep in mind:

1. Invest Only in the Best Technology

What this means is investing in the right automated software for your procurement strategy. This is already a given since, with every procurement strategy, good software is a must.

Make sure that the tool you are investing in is working, has a good interface, and is full of features that cross over to other procurement functions, such as sourcing and data analysis.

2. Developing a Strategic Sourcing Plan

Strategic sourcing works well with indirect procurement. It allows the procurement team to find the best possible suppliers while following the company’s goals.

3. Partnering with a Group Purchasing Organization

Since it deals with buying supplies that are meant to keep the company in working condition, then partnering up with a group purchasing organization is ideal. GPOs can help you balance your expenses and it reduces supplier risk. The move also saves you time and money.

4. Proactive Change Management

Since this procurement strategy demands people who know exactly what they are doing if you ever need to change some of the members of your team, then it is always a good idea to do so.

Training new members can also help and there is certainly a rising boom for procurement analysts and procurement managers nowadays.

Also, choosing your software vendor is a part of this process. If you found a good software vendor for all the automated software needed for the procurement process then you are certainly lucky.

Conclusion

In conclusion, indirect procurement plays a vital role in the overall functioning of a company. While it may not always be the main focus, its significance lies in efficiently acquiring services, resources, and support that enable the smooth operation of business activities.

It ensures that essential needs are met, such as legal assistance, office supplies, and facility management, contributing to the company’s effectiveness and productivity.

By carefully managing indirect procurement, companies can optimize spending, maintain quality standards, and enhance operational efficiency.

Frequentlyasked questions

What is indirect procurement?

Indirect procurement is the process of buying/procuring supplies that are instrumental to the daily operations of the company.

How to do indirect procurement?

Like most procurement processes, indirect procurement requires data gathering and the sourcing of potential good suppliers.

How is indirect procurement different from normal procurement?

The latter is all about buying supplies for the growth of the company. The former, however, is all about buying supplies for the daily operations of the company.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.