ChatGPT & AI in

Procurement Course

Free Preview Lesson

Written by Marijn Overvest | Reviewed by Sjoed Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

Procurement Process: Master 7 Essential Steps in 2024

Key takeaways

- A procurement process is a process of buying or procuring supplies for the company.

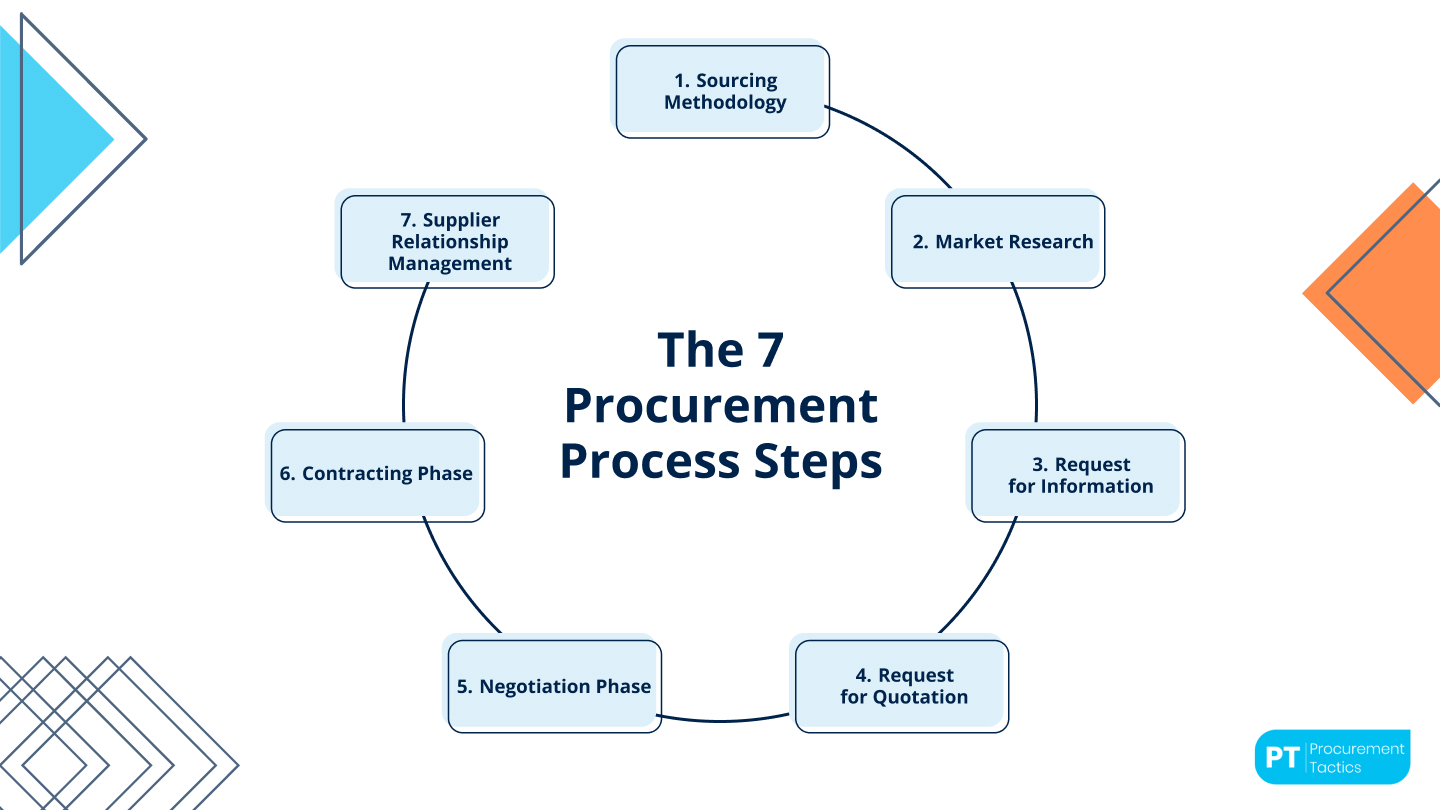

- The procurement process is made up of a sourcing methodology, market research, RFI, RFQ, negotiation, contract management, and supplier relationship management.

- Delays and poor visibility can mean that your procurement process is outdated.

The procurement process is a vital part of many businesses, especially now that e-commerce has skyrocketed. However, procurement is still unknown to many yet it plays a crucial role in the success of a business.

In this article, we are going to talk about the procurement process. We are going to show you the steps you need to take to streamline your procurement process. We will also show you a real-life example of how the seven steps in procurement can be undertaken. Further, we have interviewed a procurement expert to give you insights about the world of procurement.

After you read this article, you will have the right amount of procurement knowledge. You will also be able to use the techniques you learned here in your own procurement to improve your processes.

Furthermore, I have created a free-to-download editable procurement process: 7 steps template. It’s a PowerPoint file, together with an Excel file, that can help you streamline your procurement process. I even created a video where I’ll explain how you can use this template.

What is the Procurement Process?

Google the term “procurement process” and you’ll end up with a lot of search results.

Every expert in the field of negotiations and procurement has their procurement process, and they’d very much want you to follow their ways too.

Some processes are either too complex or too simple that the actual important information needed for each process is forgotten or not discussed.

Thus, needing a clear, practical, and simplified procurement process is needed. And that is what we are going to aim for with this article.

Have a look at the image below:

Having a simple yet efficient procurement process will not just save you time and effort, but resources as well. The time saved can be spent on other important tasks, such as sourcing for other suppliers, canvassing for other solutions, and others.

Let’s now define what the procurement process really is.

The procurement process involves finding, agreeing to terms, and acquiring goods, services or works through tendering or competitive bidding. Its added value within organizations is to ensure that buyers receive the best possible price when considering factors such as quality, quantity, time, and location.

In essence, procurement helps companies obtain the best prices for their goods, gain knowledge about their suppliers, negotiate better contracts, and ensure quality control. In many companies worldwide, they drive profit margins.

The 7 Procurement Process Steps

Now that you know what the procurement process is, it’s time to learn the seven procurement steps that will help you streamline your procurement process.

Step 1 – Sourcing Methodology

Before we start discussing how sourcing methodology is done, we will first differentiate it with sourcing strategy and sourcing policy.

The sourcing methodology is the structured framework for sourcing. Simply, this is like the roadmap that guides your sourcing process.

The sourcing strategy is different as it is the specific approach or plan within that process that will help you achieve your sourcing goals.

On the other hand, we have a sourcing policy that is different from the other two. The sourcing policy is the overarching guidelines and rules that govern how sourcing activities should be conducted, ensuring they align with organizational standards and regulations.

Now that we have differentiated these three, it’s time to explain how you will conduct the sourcing methodology.

The first step in setting up your sourcing methodology is to have a clear assignment of what you want. This assignment serves as a foundation for the sourcing process, ensuring that everyone involved understands what needs to be achieved and how to go about it.

Nonetheless, you also need to secure management commitment and stakeholders’ support in order to push through with what you want to achieve.

After you have a clear picture of your sourcing goals and support from the management, your next step is to form a sourcing team that will help you realize your sourcing goals.

Once you have gathered the best people for your team, you will now conduct various analyses. These analyses include: analyzing the current purchasing situation, analysis of the internal process, financial analysis, contract analysis, market analysis, and portfolio analysis.

Once you are done with your analyses, you must now interpret the conclusions that you have gained from them. The outcome of the analyses will determine your sourcing methodology.

Step 2 – Market Research

The assignment to buy goods or services can come from companies, managers, or procurement managers themselves. More about that in step 3, but before a procurement manager starts buying supplies, there must be a need for the said supply.

Therefore, it’s the procurement manager’s responsibility to recognize the need for supplies and to develop market research for the said supply.

Market research will help the procurement manager come up with the exact number or amount of the needed supplies.

For example, an IT company has around 40 people coming in as new hires and there are only 20 computers for use.

The procurement manager’s market research must have data and research that will help him/her in making sure he knows everything needed for buying additional computers for the growing company.

Some of the questions that a procurement manager should ask during market research should be the following:

- Does the company have a current supplier?

- Does the company have an alternate supplier in case the original supplier is gone?

- Does the company have an ample budget for procurement?

- Is there a shortage of the material that the company is trying to procure?

- If yes, will this affect our company’s budget allocation for the procurement?

- Is there an alternative if the supply needed is not available?

The market research should also cover sourcing for new available suppliers. Depending on the company or not, sourcing specialists can help the procurement manager identify new sources of supplies.

Finally, the market research helps in identifying key information needed for the next steps. Information such as pricing per supply and brand quality is important and should be included in the research.

Step 3 – Request For Information (RFI)

The third step involves asking for information not just from suppliers, but from the heads of the department or branch that needs the supplies.

Before you create a purchasing order, you will need to come up with the exact number of supplies needed. Information such as the number of available supplies and the pricing per supply are just some that you can ask when making the request.

At this stage, you must also ask yourself the following questions:

- Which department or branch in the company needs the supplies?

- How many supplies are needed?

- How long should supplies last? A month? A year?

- Does the branch already have a reliable supplier?

- Is there an opportunity to look for new suppliers?

- How much budget is allocated for the said supply?

- What quality preferences or other product requirements do I have?

Once the procurement manager has enough data, a purchase request is then sent to higher management for budget approval. This is where company management will then decide how much budget is given to the procurement manager, based on data that was given by the initial market research.

The RFI can be considered a part of the process where you ask for more information from the branch managers, sourcing specialists, and others involved.

During my time as a sourcing manager at the largest food retailer in the country, I frequently worked with RFIs. There are many advantages to using an RFI.

In my opinion, the main benefit is that you can efficiently send the same information to multiple suppliers.

An alternative could be having a conversation with one supplier, which can create tunnel vision and lead to ultimately going with that supplier. By working with RFIs, you broaden your horizon, which ultimately leads to a wider range of prices.

Step 4 – Request For Quotation (RFQ)

The request for quotation is part of the procurement process where you ask suppliers for their initial pricing for the supplies needed. Usually done by letter, the procurement manager sends the request while the supplier responds by giving the initial price for the supplies.

For an idea of what to ask the supplier, here are some questions that one can ask:

- Does the supplier have a warehouse for the supplies?

- Where are the supplies located?

- For materials supplied outside of the country, how long will delivery take?

- For materials supplied locally, how long will delivery take?

- How much is the initial price per supply?

- Is there a shortage of the said supplies right now?

Once a reply from the RFQ or request for quotation is received from the supplier, the procurement manager should hold a meeting to discuss the quotes given.

A detailed analysis for each pricing is considered while the initial market research will give the procurement manager an idea of how much each supply is priced at a market level.

The information from the market research, once again, is invaluable because it will give the procurement manager an edge when proceeding toward the next procurement process.

Step 5 – Negotiation Phase

Perhaps the most challenging yet exciting phase during the procurement process, the negotiation phase is where the procurement manager tries to get or procure the supplies either at a reasonable price or amount.

Negotiations can also extend towards the procurement manager offering concessions to the supplier in the hopes of doing more business in the future.

During the negotiation phase, the negotiator should consider asking the following:

- Is there an ample amount of supplies for the order?

- Are there special discounts that the negotiator can take advantage of?

- Who is the contact person for the supplier and the company?

The negotiation phase is also the event where the skills of a professional procurement manager may shine; once successful, this means he/she has proved his/her mettle as a master negotiator!

During the negotiation phase, always make sure to be ready with the information you gathered during the market research phase.

Step 6 – Contracting Phase

The contracting phase is where the procurement manager takes care of all contracts, invoices, receipts, and documents that were signed and are needed during, before, and after the entire procurement process.

During the contracting phase, there are only a few questions involved, but to make the process smooth, the procurement manager should check on the following:

- Were the supplies delivered in good condition?

- Were there any delays with the delivery?

- How can the supplier avoid delays (if they happen) in the future?

- Was payment settled with the supplier?

Most companies employ the use of procurement software to keep all important data and documents stored digitally. For more traditional companies, the procurement manager has to keep track of all receipts and must store them for future reference.

The contracting phase is also important because if there is a need to procure more supplies from the same supplier, all contracts, documents, and receipts can be used for market research once more.

Step 7 – Supplier Relationship Management (SRM)

The final step is supplier relationship management (SRM). After completing all the previous steps, you now focus on assessing and establishing a robust relationship with your chosen supplier, but also with the suppliers who did not receive the contract.

It is very important to also have a good relationship with them since you need them in further negotiations to make sure that you have an alternative in case you want to switch suppliers

In this phase, active collaboration with your chosen suppliers is also essential to ensure they fulfill their commitments and deliver the agreed-upon goods or services.

Regular communication, performance evaluations, and feedback exchanges are part of this process, helping to address any concerns, identify areas for enhancement, and foster ongoing growth.

Moreover, supplier collaboration goes beyond the conventional buyer-supplier dynamic, emphasizing the creation of strong partnerships built on trust, transparency, and shared goals.

By nurturing these relationships, you can strengthen your supply chain and ensure successful long-term partnerships with your suppliers.

Real-Life Example of The 7 Procurement Process Steps

Nestle is on a mission to achieve its goal of net zero and transition towards a regenerative food system. The company recognizes the importance of how raw materials are produced and sourced.

Thus, Nestle instituted a plan to focus on plant science, dairy livestock, agricultural systems science, and their environmental impacts. Additionally, it plans to work in close collaboration with its internal and external partners to achieve its goal.

Although Nestle has their way of sourcing suppliers, it still follows the usual process of procurement which involves identifying its sourcing methodology, market research, Request for information, Request for quotation, negotiation phase, contracting phase, and supplier relationship management that we are going to discuss with you.

1. Sourcing Methodology

Nestle obtains its products through trade channels, using its procurement organization or directly engaging with farmers through Nestle’s Farmer Connect Team.

The foundation of Nestle’s sourcing approach lies in its responsible sourcing framework, a mandatory practice within the company. They follow the “Nestlé Responsible Sourcing Standard” to ensure adherence to responsible sourcing principles.

2. Market Research

In market research, Nestle ensures that all the suppliers work according to the same principles and values that it uses for itself. This is because their ultimate goal is to do business sustainably which will preserve itself and the environment for future generations.

One of their commitments is that they will ensure that the raw materials they will source are not associated with damaging existing rainforests.

They also have a policy that they follow which is the Nestle Responsible Sourcing Standard that describes the requirements and ways of working that they apply together with their suppliers to ensure the sustainable long-term supply of materials and services

3. Request For Information (RFI)

For Nestle, their procurement will be involved at the beginning of any process relating to commercial discussions and supplier selection.

The procurement department of Nestle will handle the overall sourcing process, lead supplier selection decisions, and recommend the suppliers they choose to the business stakeholders.

The department’s involvement at the beginning of the sourcing process will allow Nestle to have an appropriate analysis of supply risks and measures to counter those risks.

Additionally, Nestle’s sustainable sourcing is built on its own Responsible Sourcing Standard that sets out basic non-negotiable standards and crucial sustainability practices that it requires for its suppliers, employees, agents, and subcontractors to meet its goal.

4. Requisition For Quotation (RFQ)

As Nestle is a multinational company, it has an excellent sustainable sourcing team that ensures that the raw and packaging materials that it sources from its suppliers meet its standards.

This is because every year, Nestle sources an average of 25 million tons of raw and packaging materials, along with services and indirect materials.

All significant purchases of Nestle will undergo a competitive bidding process to ensure that it is consistently acquiring competitive cost, service, and quality from its suppliers.

Nestle has a prequalification for potential suppliers that will be undertaken to create a shortlist of suppliers. This will ensure that Nestle will have an early understanding of the potential supplier’s capability. Nestle’s requirements are according to:

- Food/packaging safety and quality

- Technical and R&D Capabilities

- Responsible sourcing

- Financial stability

Nestle will only invite the shortlisted suppliers to participate in the quotation process or request for proposal.

5. Negotiation Phase

Once the suppliers provide their proposals, the shortlisted suppliers will be evaluated against a predetermined set of evaluation criteria to know if they meet all the requirements of Nestle.

The evaluation criteria of Nestle contains:

- Specifications

- Price Conditions

- Service Conditions

- Food/ packaging Safety and Quality

- Technical, R&D, and Innovation Capabilities

- Responsible Sourcing

- Financial Stability

All important information regarding the supplier’s proposal and any risks associated with the supplier or the delivery of materials will be shared with Nestle to ensure that informed decisions are made that take into account all the relevant details.

Additionally, potential suppliers of Nestle will be further assessed to ensure the compliance of each of their supplying sites. The key focus of supplier assessment will be:

- Responsible Sourcing

- Food/Packaging Safety and Quality

This assessment will be used to make an approval decision as to whether the supplier can or cannot be used to supply goods or services to Nestle.

6. Contracting Phase

Once selected, the supplier must abide by the Nestle Supplier Code when delivering their goods to Nestle.

Furthermore, procurement agreements and transactions will be approved by duly authorized personnel within Nestle and the supplier’s organization.

A formal approval process will be documented that includes approval levels, roles, and responsibilities of all parties.

7. Supplier Relationship Management (SRM)

Nestle utilizes a supplier portal to facilitate effective collaboration with its global supplier base. The portal grants suppliers secure access to essential processes and tools, allowing them to manage contract-related information, bidding, ordering, delivery, and payment activities efficiently.

Procurement Expert’s Advice on Procurement Process

For this article, we asked a seasoned procurement professional to share his insights regarding procurement process.

Sjoerd Goedhart

Owner, Goedhart Interim Management & Consultancy

LinkedIn Profile: https://www.linkedin.com/in/sjoerdgoedhart/

1. Can you share a personal example of the procurement process? What can readers learn from this?

“In organizations, outdated procurement processes can lead to delays, errors, and poor visibility. Manual or complex systems may result in missed opportunities, higher costs, and strained supplier relationships.”

2. What should readers know about the procurement process?

“There are various steps that need to be taken in the procurement process. It is wise to always go through all 7 steps of the process to arrive at an offer, negotiation, and final choice.“

3. What is the biggest misconception about the procurement process? What do most people get wrong about this?

“Many underestimate the prevalence of manual procurement processes in companies, despite the associated costs and risks.“

4. What are some common inefficiencies in traditional procurement processes, and how can they be addressed?

“Common inefficiencies in traditional procurement processes include manually onboarding new suppliers, procurement employees manually entering data, handling paper invoices leading to increased costs and error risks, and difficulties in matching invoices with PO numbers.

These inefficiencies can be addressed through the implementation of procurement software, which automates processes, reduces risks, and brings efficiency by unifying procurement practices across the organization.

An example is using software to automate invoice processing as part of the procurement system.“

5. How is technology transforming the procurement process, and what are the benefits and challenges?

“Technology can make the process more efficient by making information available more quickly at certain steps. Improved analyses can also be made in a specific step and if the overall process becomes more efficient, this can result in cost savings.“

6. Do you think there is a perfect procurement process?

“No, there is no perfect procurement process. I do think that with every new tender, it is important to look at the process again, to follow the entire process, and to determine in which phases certain accents are placed to achieve an optimal result.”

7. Is it ethical for procurement professionals to integrate AI into the procurement process?

“I think so. I think AI will have a major impact on the procurement process. From having more data and better analyses to more efficient processes, thus achieving cost savings.“

Conclusion

Understanding the intricacies of the procurement process is indispensable for any procurement manager, whether seasoned or aspiring. This journey involves a series of steps, from identifying needs to supplier relationship management, all aimed at acquiring goods and services efficiently.

While the process may seem straightforward—decide, locate, receive, and pay—the reality is more nuanced. The quest for a simplified yet effective procurement process is underscored, emphasizing the importance of clarity and practicality.

In this comprehensive guide, the seven critical steps are explained, accompanied by a real-life example from Nestle, a global giant committed to responsible sourcing. Each phase, from sourcing methodology and market research to negotiation, contracting, and supplier relationship management, is meticulously outlined.

The significance of responsible sourcing standards, prequalification of suppliers, and the negotiation phase’s strategic evaluation criteria are highlighted. Nestle’s commitment to sustainability, reflected in its Responsible Sourcing Standard, exemplifies the alignment of procurement processes with overarching organizational goals.

In essence, this guide equips procurement professionals with a strategic roadmap, emphasizing not just the “what” but the “how” of navigating the complex terrain of procurement. As businesses evolve, so too must procurement strategies, ensuring a seamless and sustainable flow of goods and services.

Frequentlyasked questions

What is a procurement process?

A procurement process is a process of buying or procuring supplies for the company.

How to create a good procurement process?

To create a good procurement process, there should be ample time for market and product research, good sourcing of suppliers, and data gathered from all sources through a fully working automation process.

Can you provide a real-life example of a company following the procurement process?

Nestle serves as a prime example. They emphasize responsible sourcing, conducting market research, utilizing a stringent supplier selection process, and focusing on sustainability throughout their procurement journey.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.