Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

10 Best AI Tools For Demand Planning

Table of contents

- AI demand planning is the use of machine learning and real‑time data analytics to generate accurate, dynamic forecasts that replace manual spreadsheet models.

- AI demand planning leverages internal and external data sources (such as sales history, market indicators, and seasonality) to refine predictions and optimize inventory levels continuously.

- AI demand planning automates pattern detection and adaptive learning, enabling organizations to anticipate demand shifts, reduce stockouts, and lower carrying costs.

What is AI Demand Planning?

AI demand planning applies machine learning and AI algorithms to traditional demand planning by ingesting vast internal and external datasets, ranging from historical sales and seasonal trends to real‑time market indicators. These systems automatically detect complex patterns and nonlinear relationships, producing more accurate and dynamic forecasts than manual spreadsheet models.

Beyond higher forecast precision, AI demand planning continually refines its predictions through adaptive learning, enabling real‑time adjustments as consumer behavior and market conditions shift. This agility minimizes both overstock and stockouts while seamlessly integrating with procurement and production processes to create a more responsive and cost‑efficient supply chain.

10 AI Tools for Demand Planning

1. Blue Yonder Luminate Demand Planning

Blue Yonder’s Luminate platform utilizes patented AI and machine learning algorithms to enhance forecast accuracy by up to 12% through advanced feature engineering, demand sensing, and real-time collaboration.

It ingests both internal (sales history, promotions) and external (market indicators, weather) data to generate highly reliable forecasts and automate exception management.

Planners can run what‑if scenarios in seconds, optimize inventory levels, and coordinate across teams in a unified cloud environment. Continuous learning capabilities adapt models as new data arrives, ensuring agility in volatile markets.

Price:

On request.

2. o9 Solutions Digital Brain (Demand Planning)

The o9 Digital Brain platform provides end‑to‑end demand planning by unifying data into a single semantic layer and applying AI/ML for demand sensing, probabilistic forecasting, and risk scenario analysis.

It supports collaborative workflows, event‑driven alerts, and dynamic scenario planning, enabling planners to identify early signs of demand shifts.

Industry‑specific templates accelerate deployment, while cloud‑native scalability handles large SKU/location matrices. Real‑time KPI dashboards foster alignment across functions, and continuous model retraining incorporates new data without manual intervention.

3. ToolsGroup SO99+

ToolsGroup’s SO99+ is a service‑driven supply chain planning suite that employs self‑learning, probability‑based forecasting to model intermittent and lumpy demand across all SKUs and locations.

It combines multi‑echelon inventory optimization with demand sensing to right‑size safety stocks and reduce fill‑rate errors.

Automated exception management highlights critical forecast deviations, while what‑if analyses enable rapid “what‑if” exploration of inventory and service‑level trade‑offs. The single adaptive algorithm removes the need for manual model selection, accelerating time to value.

Price:

On request.

4. Kinaxis Demand AI (RapidResponse)

Kinaxis Demand AI (formerly Demand Planning in RapidResponse) blends statistical models, event‑based inputs, and AI‑driven demand sensing to produce consensus forecasts across short and long horizons.

Planners can drill into root‑cause analytics to understand which factors (e.g., promotions, weather) drive forecast changes. Its concurrent planning engine propagates updates instantly across end‑to‑end supply chain plans, reducing replanning cycles from days to minutes.

Interactive dashboards and scenario simulations support cross‑functional collaboration and risk mitigation.

Price:

On request.

5. SAP Integrated Business Planning – Demand Planning

SAP IBP’s Demand Planning module leverages machine learning, time‑series forecasting, regression, and demand sensing to generate accurate baselines without requiring deep data‑science expertise.

Collaborative features allow sales, marketing, and supply chain teams to inject market insights, manually adjust forecasts, and achieve consensus. AI‑assisted outlier detection and automated adjustments to ordering patterns refine plans continuously.

Integrated what‑if simulations and real‑time alerts enable planners to model disruptions and optimize inventory across multilevel networks, all on SAP HANA’s in‑memory platform.

Price:

On request.

6. Oracle Demand Management Cloud

Part of Oracle Supply Chain Planning Cloud, Oracle Demand Management Cloud applies built‑in AI and machine learning to produce probabilistic forecasts, demand modeling, and scenario planning.

It integrates demand insights with supply constraints, stakeholder inputs, and external signals (e.g., macroeconomic data) to optimize inventory and minimize stockouts.

Real‑time dashboards and alerts foster collaboration, while seamless integration with Oracle ERP delivers end‑to‑end visibility.

Price:

Subscription pricing starts at $75 per user/month for cloud editions; on‑premise perpetual licenses start at $300 per user plus 22 % annual maintenance.

7. Anaplan Demand Planning

Anaplan offers an AI‑infused, cloud‑native demand planning application that connects multiple data sources (historical sales, promotions, external drivers) and applies machine learning to reduce forecast bias.

It features configurable templates, automated exception alerts, and collaborative workflows that let cross‑functional teams adjust baseline forecasts with promotional uplifts and lifecycle changes. Real‑time scenario modeling and dashboarding enable planners to evaluate “what‑if” outcomes instantly.

The platform’s flexible modeling engine scales from departmental pilots to enterprise‑wide deployments.

Price:

On request.

8. Demand Works Smoothie

Smoothie Desktop is a demand planning and S&OP solution featuring statistical forecasting, inventory segmentation, and multi‑tier supply planning within a browser‑based interface.

It offers automated “best‑fit” algorithms, scenario simulation for service‑level and lead‑time trade‑offs, and integrates seamlessly with host ERP systems via two‑way automated data exchange.

Scalable to the server edition (Smoothie Server), it supports high‑volume, multi‑user workflows with advanced security and concurrent access.

Price:

Contact vendor for pricing.

9. Forecast Pro

Forecast Pro is a standalone forecasting application designed for business analysts.

It offers automatic statistical and machine learning model selection, a “best‑pick” algorithm, exception reporting, and collaboration via Excel integration.

Unlimited item forecasting, hierarchy mapping, and what‑if simulation support comprehensive S&OP processes.

Price:

Licenses are annual subscriptions in three editions: Forecast Pro 100 ($1,995/user), Extended ($5,200/user), and TRAC ($7,875/user), with volume and academic discounts available.

10. Prevedere

Prevedere (now part of Board) provides AI‑driven predictive analytics that fuses internal performance data with over 5 million external macroeconomic and industry‑specific indicators.

Its Generative AI Copilot offers natural‑language insights, scenario modeling, and continuous planning to anticipate demand shifts and economic disruptions.

The Global Intelligence Cloud continuously monitors world activity, applying econometric and machine learning models to surface actionable recommendations. It empowers cross‑functional teams with real‑time foresight for strategic and operational planning.

Price:

On request.

Comparison: Traditional vs AI-based Demand Planning

AI Demand Planning Process

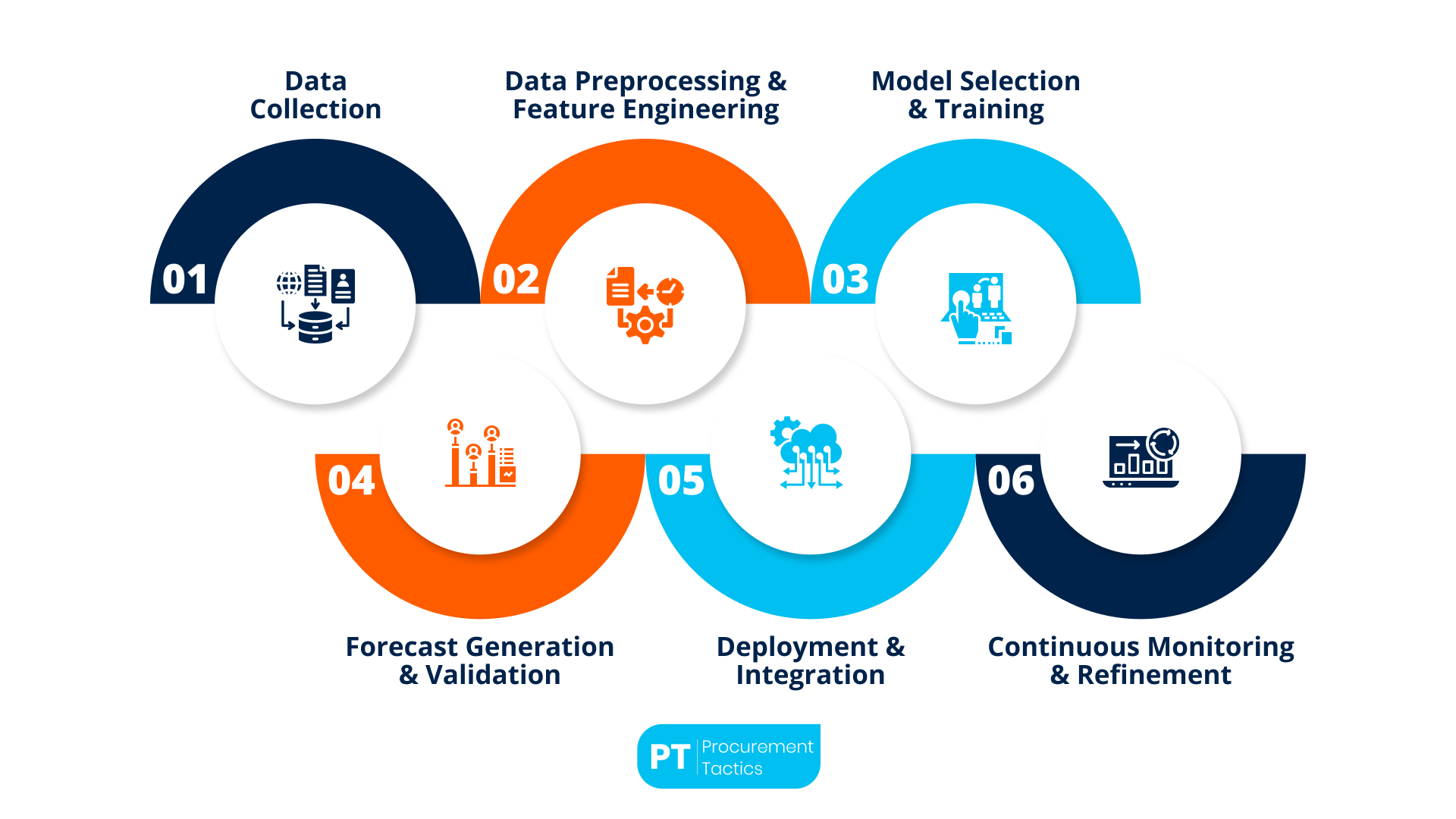

1. Data Collection

Organizations begin by aggregating all relevant internal and external data needed for forecasting. Internal sources include historical sales figures, inventory levels, and promotional calendars, while external inputs cover market indicators, economic metrics, and seasonality factors. Collecting a comprehensive dataset lays the foundation for accurate AI-driven demand planning.

2. Data Preprocessing & Feature Engineering

Raw data must be cleansed of errors, outliers, and missing values to ensure model reliability, and then transformed into predictive features such as lagged sales, holiday flags, and trend indicators. Thoughtful feature engineering (like encoding promotions or weather effects) helps machine learning models capture complex demand drivers that traditional methods overlook.

3. Model Selection & Training

Data scientists evaluate a range of algorithms, from classic time‑series regressions to advanced neural networks, using cross‑validation to compare forecast accuracy and robustness. By training models on historical data and tuning hyperparameters, they identify the architecture that best captures nonlinear relationships and demand variability for the specific business context.

4. Forecast Generation & Validation

The chosen model generates rolling demand forecasts, which are then validated against hold‑out datasets or recent actual outcomes to assess performance metrics like mean absolute percentage error. This validation step uncovers bias or seasonality misfits, enabling fine‑tuning of model parameters before full deployment.

5. Deployment & Integration

Validated AI forecasts are embedded into existing ERP, S&OP, and inventory management systems, automating the flow of insights into procurement and production workflows. Seamless integration ensures planners can access real‑time predictions directly within their familiar tools, fostering adoption and minimizing manual interventions.

6. Continuous Monitoring & Refinement

Post‑deployment, forecast accuracy is tracked via dashboards and automated alerts that flag anomalies or declining performance. Models are retrained on new data at regular intervals or triggered by significant market shifts, ensuring that demand plans evolve alongside changing consumer behavior and external conditions.

AI in Demand Planning – Examples

1. Hettich

Hettich partnered with pacemaker.ai to replace its manual, spreadsheet‑based planning across six warehouse zones with an AI‑driven forecasting tool. The move was prompted by the need to handle increasing complexity in SKU variants and volatile customer demand.

By automating data ingestion from internal ERPs and external market signals, Hettich now runs daily forecast updates with over 90 % accuracy, slashing planning lead times and bolstering inventory reliability for a more resilient supply chain.

2. Berco Aftermarket

Facing a vast portfolio of 4,000+ parts across 52 countries, Berco Aftermarket switched to an AI‑powered demand planning solution from pacemaker.ai to unify its S&OP processes. The rationale was to overcome fragmented data and high forecast variance that fueled excess stock and cash‑flow constraints.

Post‑implementation, Berco reduced forecast deviations significantly, unlocked working capital through lower safety stocks, and improved customer fill rates with more dependable product availability.

3. Danone Group

Danone Group implemented Tradecloud’s AI demand forecasting module to tackle chronic lost sales and obsolescence in its dairy segment.

Leveraging machine learning to analyze historical orders, promotions, and shelf‑life constraints, Danone transitioned from static rule‑based forecasts to dynamic, data‑driven predictions.

As a result, the company achieved a 30 % reduction in lost sales, a 30 % cut in product obsolescence, and halved the workload of its demand‑planning team.

4. Atria

Atria, one of Northern Europe’s largest meat producers, adopted RELEX’s machine‑learning demand planning after already operating a rule‑based system.

The shift was driven by the sector’s short shelf‑life products and the need for day‑level forecast granularity to minimize waste.

Integrating AI improved week‑level forecast accuracy to 98.1 %, cut manual forecast changes by 13 %, and enabled seamless unification of short‑ and long‑term planning, setting the stage for expansion into additional markets.

5. Unilever (Cold‑Chain Business)

Unilever’s ice cream division turned to AI to better correlate weather patterns with sales fluctuations in its cold‑chain operations.

By integrating predictive models that analyze meteorological data alongside point‑of‑sale records, the company moved away from simple heuristics and static historical averages.

This transition boosted forecast accuracy by 10 % in the Swedish market and drove a 12 % increase in U.S. ice cream sales through more precise production and distribution planning.

The Key Benefits of AI for Demand Forecasting

The Challenges of AI in Demand Forecasting

Conclusion

AI demand planning transforms manual, periodic forecasting into continuous, data‑driven insights that improve demand accuracy and enable proactive risk management. By leveraging real‑time and historical data, it aligns inventory with actual market needs and supports more informed decision‑making.

Despite its advantages, challenges such as data integrity, system integration, and skill shortages must be addressed through robust governance and training. Organizations that navigate these hurdles can achieve significant cost savings, enhanced agility, and truly resilient supply chains.

Frequentlyasked questions

What is AI demand planning?

AI demand planning is the use of machine learning and real‑time data analytics to generate accurate, dynamic forecasts that replace manual spreadsheet models.

What is the greatest advantage of AI demand planning?

AI demand planning delivers unparalleled forecast accuracy and agility by continuously learning from diverse internal and external data.

What is the most significant challenge of AI demand planning?

AI demand planning’s biggest hurdle is ensuring high data quality and seamless integration to generate trustworthy, actionable forecasts.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.