Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

Procurement Vs. Purchasing — 10 Key Differences

As taught in the Spend Analysis Course / ★★★★★ 4.9 rating

What are the differences between procurement and purchasing?

- Procurement is the end-to-end, strategic process of sourcing and managing suppliers, while purchasing is the transactional act of placing orders and paying for goods/services.

- Procurement focuses on long-term value, risk, contracts, and supplier performance, whereas purchasing focuses on price, approvals, and order execution.

- Procurement includes planning, negotiation, and relationship management across the supply lifecycle; purchasing mainly covers requisitions, POs, delivery follow-up, and invoice matching.

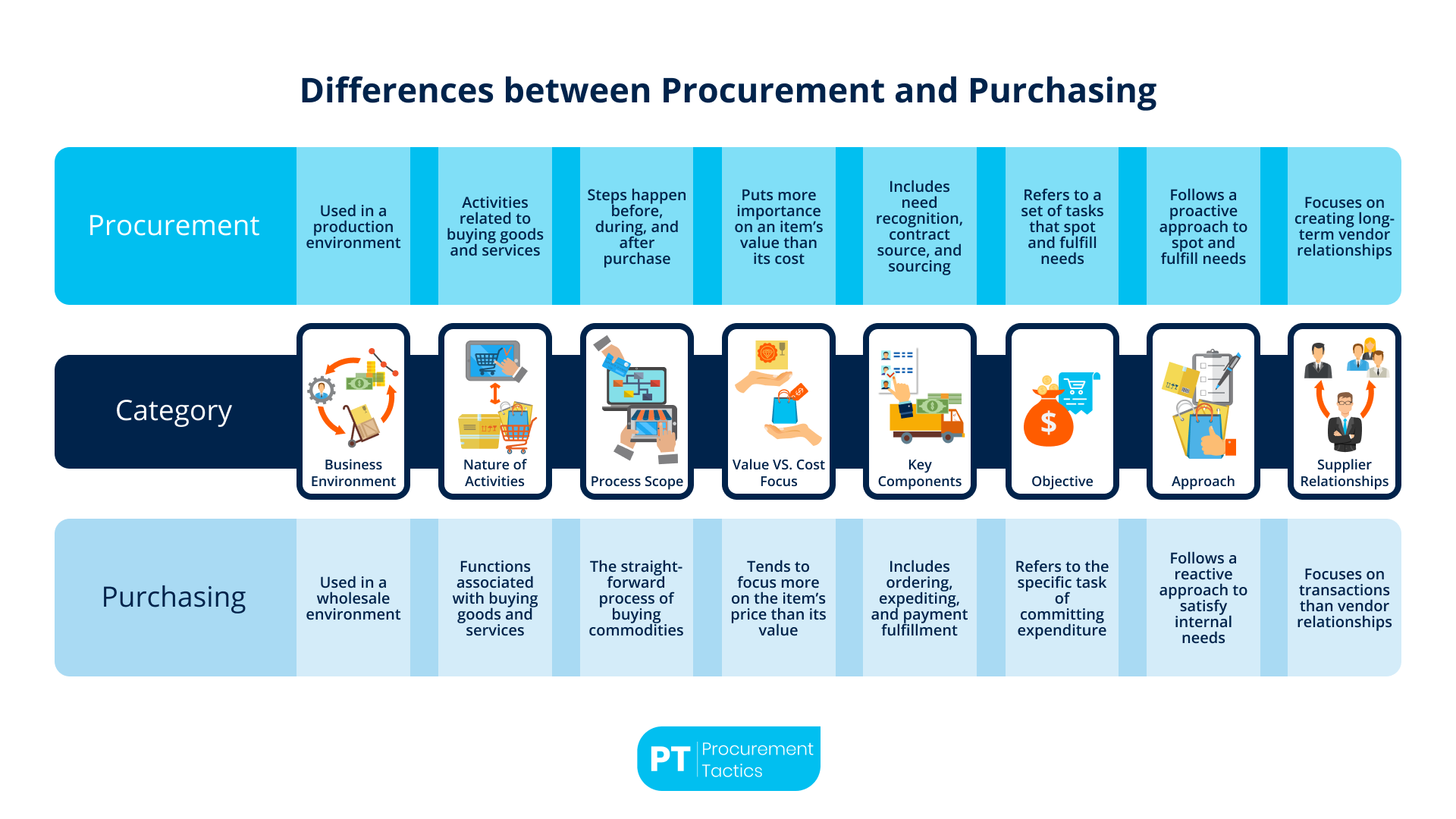

10 Key Differences Between Procurement and Purchasing

Here are the 10 key differences you may want to know about procurement and purchasing. Keep these in mind the next time someone asks you what the difference between procurement and purchasing is!

Pro Tip: Understanding the difference between procurement and purchasing is step one. The real value comes when you apply that difference to your spend data. Start by tagging transactions as either strategic procurement or tactical purchasing—this simple split can instantly reveal where your biggest opportunities (or inefficiencies) lie.

⭢ In our Spend Analysis Course, we show you how to do this in practice—turning raw spend into insights that fuel smarter decisions and stronger supplier strategies.

What is Procurement?

For the professional procurement manager, procurement means the process of identifying, shortlisting, selecting, and acquiring needed goods or services from a third-party vendor.

It can be done via direct purchase, competitive bidding, or tendering process while making sure that the delivery of the supplies is done in a timely manner.

What is Purchasing?

Purchasing is an entirely different thing from procurement. Purchasing means a set of functions that are associated with buying goods and services that the company or organization requires.

The only reason why purchasing is often associated with procurement is that it is a small subset of a broader procurement function. In simple terms, purchasing is a part of procurement.

The purchasing process always includes ordering, expediting, receiving, and fulfilling payment.

The Procurement Process

As explained, the procurement process is the process of sourcing a product or a service. So for the procurement manager, there is a set of rules and processes that need to be followed in order to build the procurement process.

A typical procurement process is usually divided into the following steps:

The Purchasing Process

To put it simply, purchasing needs. Those products/services do not affect the growth of the company but are rather just needed for its continuous operations.

Does that mean that the procurement manager won’t bother with creating a purchasing process?

The answer is a big no. A procurement manager recognizes the importance of creating a purchasing process since it enables the company to achieve short-term goals that include timing, costs, and quantity.

The typical purchasing process includes the following:

- Evaluating received RFQs

- Creating and distributing purchase orders

- Receiving products/services

- Quality assurance of received service/product

- Receiving a purchase request

- Arranging payment to suppliers

Procurement and Purchasing: Similar and Yet, So Different

In a procurement team, the terms procurement vs purchasing are often used with just one meaning in mind. Both of the terms are often associated with buying supplies or materials that probably no one cares about defining each term properly. But for a good procurement manager, distinguishing purchasing from procurement is an important skill.

The Procurement and PurchasingDefinition Table

To help procurement managers with setting definitive qualities for procurement and purchasing, we at Procurement Tactics created a simple table for such a need.

More definitions and terms are available for interested procurement managers in our Negotiation Course For Procurement Professionals.

So if we were to create a small and simple table for defining procurement and purchasing, it’d go about something like this:

Examplesof Procurement and Purchasing

Although there are many types of procurement and purchasing, they both have one thing in common: to acquire the best product or services for the best possible price. Here are some examples of how procurement and purchasing are done:

This process is where suppliers submit their bids to provide goods and services. Thus, the government or a company chooses the bid that matches their requirements.1. Competitive Bidding

2. Sole Sourcing

This process happens when there is only one supplier who can provide for the needs of the company.

3. Open Market

This happens when a company purchases goods or services from the open market without any restriction to suppliers who can provide for its needs.

4. Request For Proposal (RFP)

This document is issued when a company or the government wants to purchase goods or services but there are many suppliers who can provide for their needs.

Thus, the suppliers submit their proposals, and the company or the government will choose the proposal that matches their requirements.

5. Reverse auction

In this process, suppliers compete against each other to offer the lowest price for their goods and services. The company will choose the supplier who has the lowest price.

Conclusion

Just like we discussed earlier, procurement is about finding and getting things a company needs, like products or services. On the other hand, purchasing is a smaller part of this, where you actually buy the stuff.

So, procurement is like the big plan for managing everything the company needs, while purchasing is about getting those specific things.

Now that you get the difference between procurement and purchasing, we hope it’s clearer for you to see how they each play their own important role in making sure a company has what it needs.

Frequentlyasked questions

What is the difference between procurement and purchasing?

Procurement is a strategic process focused on selecting suppliers, managing contracts, and building long-term value, while purchasing is more transactional and deals with acquiring goods or services. Essentially, procurement involves broader planning, and purchasing handles the execution of those plans.

What is procurement in business?

Procurement refers to the strategic process of sourcing goods and services from suppliers, ensuring value, and managing supplier relationships. It involves steps like negotiating contracts and evaluating supplier performance.

What does purchasing involve?

Purchasing involves the transactional activities of buying goods or services needed by the company, such as issuing purchase orders and processing payments. It focuses on the cost and delivery of goods within a shorter timeframe.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.