Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

Purchase Order Management — Definition + Process Explained

As taught in the Category Management in Procurement Course / ★★★★★ 4.9 rating

What is purchase order management?

- Purchase order management is the complete workflow of drafting, approving, sending, receiving, and matching purchase orders, making sure the requested goods or services arrive at the promised time and price.

- Purchase order management is the set of policies, roles, and digital tools that monitor every purchase order in real time, linking requisitions, budgets, supplier confirmations, goods receipts, and invoices to keep spending compliant and transparent.

- In practice, purchase order management turns planned spending into legally binding orders, creates a clear audit trail for payments and inventory, and helps companies avoid overspending, delays, and disputes

What is Purchase Order Management?

Purchase order management is the structured, comprehensive discipline of creating, approving, issuing, tracking, matching, and archiving purchase orders so every purchase is necessary, justified, and fully documented. In practice, purchase order management sets clear standards and workflows from the initial requisition through purchase order creation and supplier dispatch to receipt, three-way or four-way matching, and closeout, so that up-to-date information on each order is always visible, budget compliant, and ready for audit.

By controlling this purchasing paper trail, organizations gain tighter spending oversight, reduce errors and fraud, improve supplier relationships, and lay the foundation for automated digital procure-to-pay processes.

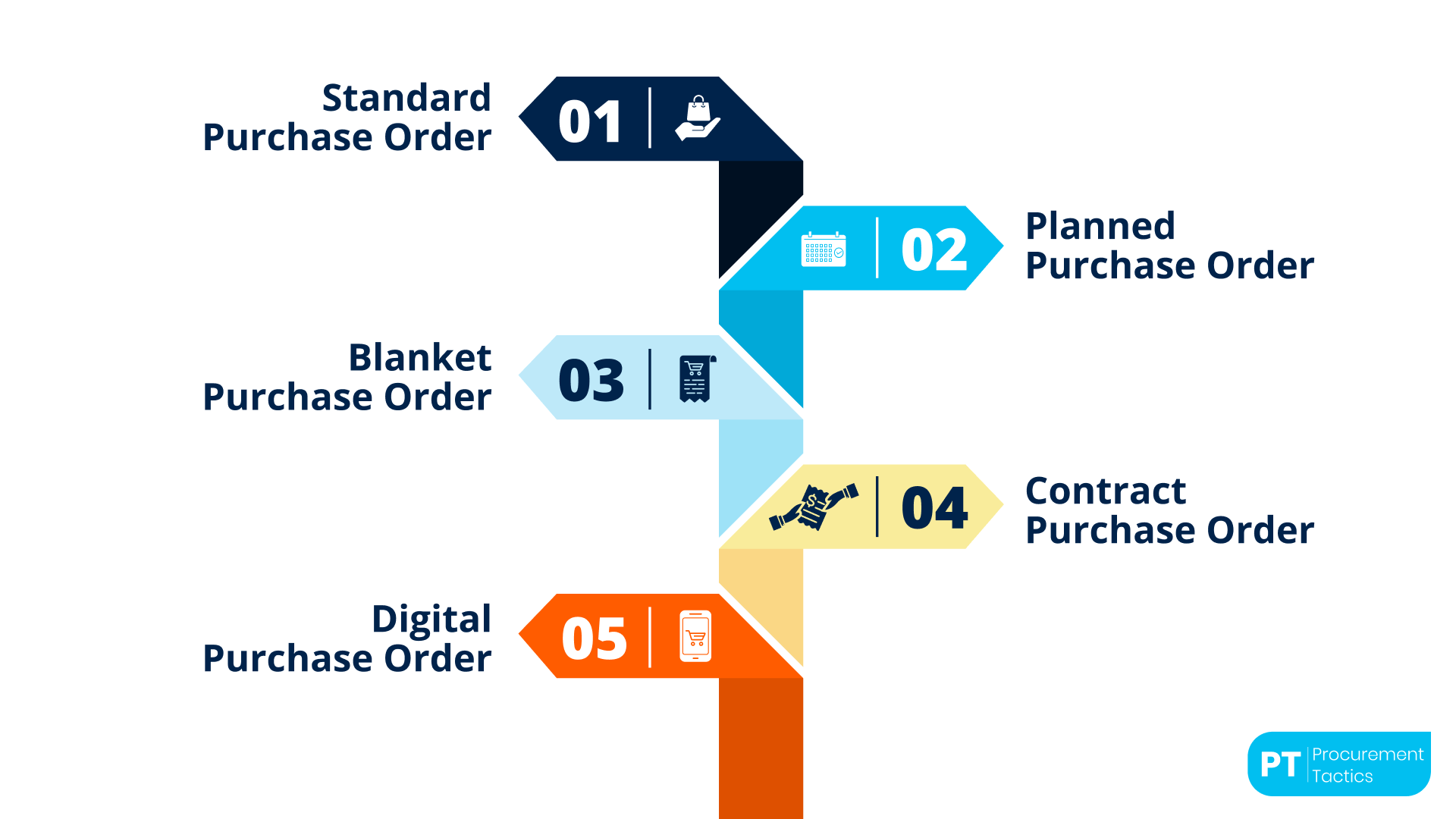

Types of Purchase Orders

Below are the following types of purchase orders:

1. Standard Purchase Order (SPO)

The classic “one-and-done” PO is used for a single, clearly defined purchase. It specifies the exact item, quantity, price, and delivery date, making it ideal when requirements are fully known and will not repeat.

Example:

Acme Inc. issued SPO # 2024-06-FURN-001 to Prime Furnitures for a one-time purchase of 2 executive desks, 10 ergonomic chairs, 4 filing cabinets, and related items worth $8,690, with a fixed 12 July 2024 delivery date and Net-30 terms.

Because every SKU, quantity, unit price, and ship-to address is locked in, the supplier can fulfil the order in a single shipment while Acme’s finance team can three-way-match the incoming invoice against the PO and goods receipt with zero ambiguity.

2. Planned Purchase Order (PPO)

A framework for future buys when you know what you’ll need and roughly how much, but the precise schedule is still uncertain. Each release under the plan finalises quantities and dates as they firm up.

Example:

Fashion retailer Rainy Day Outfits opened PPO # 2024-PPO-FALL-001 with knitwear supplier Jolly Hosiery to secure an estimated volume of fall-season tops and cardigans.

The agreement fixes price ranges and an overall budget up-front but leaves release quantities and exact ship dates flexible; every two weeks, the buyer issues a “release” that finalises colour mix and required units for August-to-October deliveries, letting production scale with real-time sales trends while guaranteeing capacity and pricing.

3. Blanket Purchase Order (BPO)

Covers recurring orders of the same goods or services over a set time horizon. It lets buyers draw multiple releases against one PO number, usually with a total-spend ceiling, reducing paperwork and accelerating replenishment.

Example:

Elvis Fine Dining runs a year-long BPO (PO # 2024-PPO-PRODUCE-001) with Beet Street Produce, covering a projected $ 120k of fresh fruit and vegetables.

Bi-weekly electronic releases reference the master PO to call off Monday and Friday drops, while the restaurant benefits from menu-based flexibility and the vendor enjoys predictable demand.

An overall spend ceiling, quality specs, and locally-sourced preference clauses sit in the header, so the paperwork happens only once instead of dozens of times across the year.

4. Contract Purchase Order (CPO)

A legally binding umbrella agreement in which commercial terms (pricing, service levels, liabilities) are locked in first; detailed call-offs for quantity and timing follow later. CPOs suit long-term, strategic supplier relationships where flexibility and pre-negotiated protections are critical.

Example:

Golden Gate Hotel signed CPO # 2024-CPO-BEDDING-001 with Comfort Beddings Inc. for a two-year term (12 Jun 2024 – 11 Jun 2026).

The contract purchase order locks payment terms, quarterly price-review rules, minimum $2 k release value and service-level warranties for mattresses, duvets and linens, but leaves exact items and quantities to be detailed in future call-off POs that the hotel’s purchasing manager can raise within four business days of need, streamlining replenishment while preserving the ability to negotiate price adjustments each quarter.

5. Digital Purchase Order (DPO)

Not a new legal form but a technology-enabled version of any PO type. A DPO is created, approved, dispatched, and tracked within an e-procurement platform, giving real-time visibility, automated matching, and lower error rates across standard, planned, blanket, and contract orders alike.

Example:

“MEGA COMPANY” replaced paper forms with a no-code digital PO app built on the Forms2 platform.

The system auto-checks its supplier database for the lowest current price, populates the PO, routes it for mobile approval, and writes the transaction straight into the ERP, slashing manual data entry, accelerating approvals from days to minutes, and generating analytics that cut material costs and boosted PO throughput.

This case shows how any PO type (standard, blanket, etc.) becomes far more agile once fully digitised.

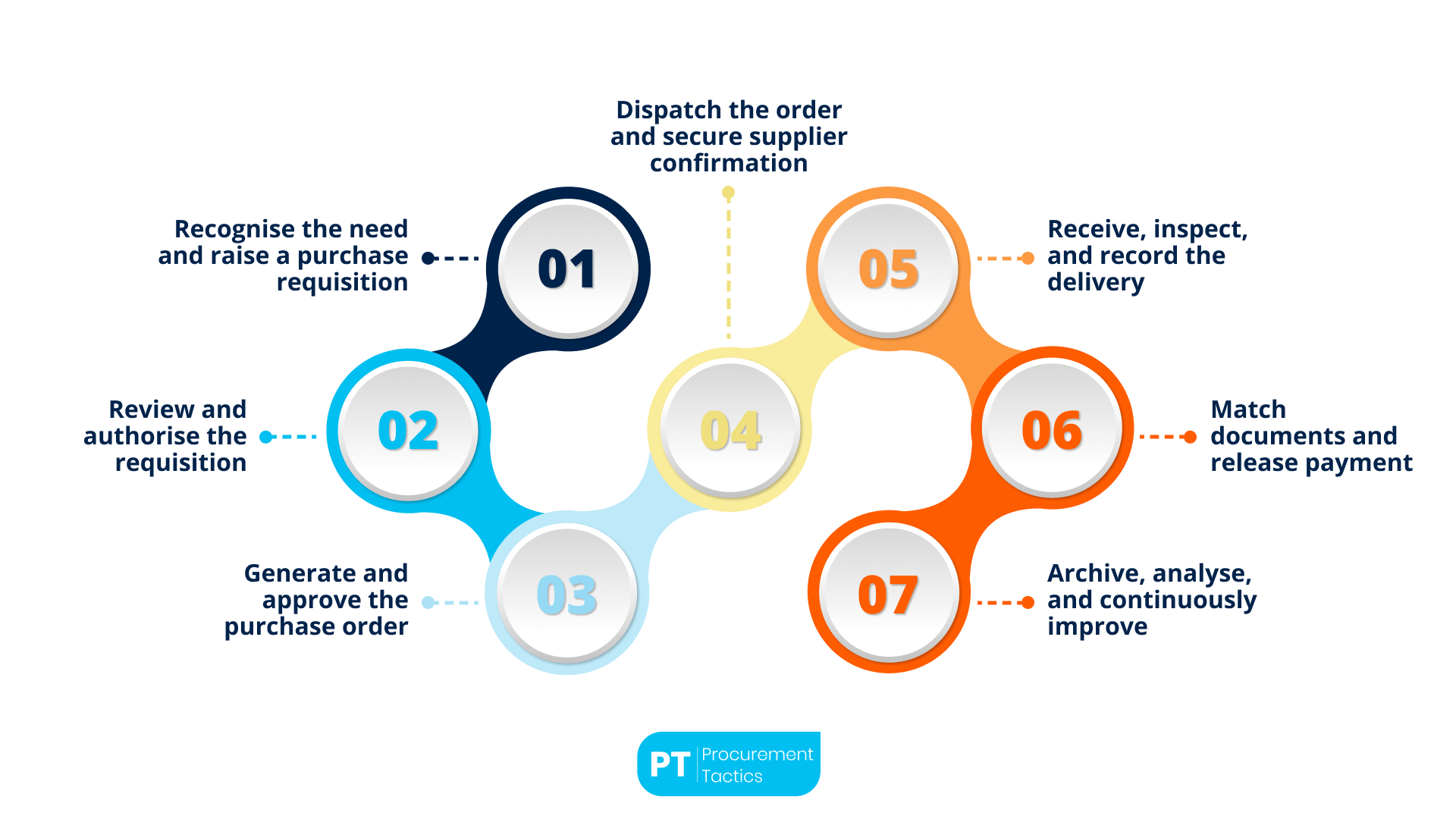

Purchase Order Management Process

Purchase order management runs through a repeatable chain of activities that turn an internal need into a paid-for, fully documented delivery.

Although wording differs from one framework to another, the flow can be grouped into seven large stages.

1. Recognize the need and raise a purchase requisition

A department identifies a requirement for goods or services and submits a formal requisition that specifies quantity, specification, required date, and business justification.

This intake step captures demand in a single channel and starts the approval workflow.

Example of how to recognize the need and raise a purchase requisition:

When the maintenance team sees that its stock of replacement conveyor belts has dropped below the safety threshold, the supervisor opens the company’s e-procurement portal and completes a standard requisition form.

She selects the approved belt SKU from a dropdown list, enters the required quantity of 12 units, specifies delivery within five working days to avoid unplanned downtime, and adds a brief business justification citing preventive-maintenance schedules.

Once submitted, the system logs the request, routes it to the plant manager for one-click approval, and automatically launches the purchase-order workflow, capturing demand through a single channel while ensuring traceability from need identification to PO creation.

2. Review and authorize the requisition

Budget holders, line managers, or category leads verify that the request is aligned with policy, budget, and strategy.

Electronic approval routes prevent unauthorised spending and provide an audit trail before any commitments are made.

Example of how to review and authorize the requisition:

Once the maintenance supervisor submits the belt requisition, the e-procurement system instantly checks the item’s contract price and remaining plant-maintenance budget.

It then pings the plant manager and the category buyer in a sequential workflow; each receives a mobile push notification showing the requisition details, budget impact, and policy compliance score.

With one tap, the plant manager confirms operational need, while the buyer verifies the SKU against the approved vendor list and confirms that the unit price matches the negotiated rate.

Their digital signatures are captured automatically, locking the requisition against edits and generating a time-stamped audit trail, ensuring spend is authorised, policy-compliant, and ready for PO creation without email back-and-forth.

3. Generate and approve the purchase order

Once authorised, requisition data “flips” into a purchase order form that lists product or service details, agreed price, terms, delivery instructions, and legal clauses.

The purchase order is routed for final sign-off (often finance or procurement) so that every order is contractually sound before it leaves the organization.

Example of how to generate and approve the purchase order:

After the requisition receives all policy and budget approvals, the e-procurement platform automatically converts its data into a draft purchase order, pre-filled with the conveyor-belt SKU, contract price, Incoterms 2020 delivery terms, and the plant’s dock-door instructions.

A built-in rules engine appends standard legal clauses (liability limits, warranty language, anti-bribery wording) and validates the supplier’s tax ID and bank account against the vendor master.

The system then routes the PO to the finance controller for a final compliance and cash-flow check; she reviews the spend impact on the monthly forecast directly inside the workflow, adds a digital signature, and clicks “Approve.”

The PO status flips to “Issued,” a PDF copy is archived for audit, and an electronic order is dispatched to the supplier’s portal, ensuring every outbound commitment is contractually sound, fully approved, and traceable without manual re-keying.

4. Dispatch the order and secure supplier confirmation

The approved document is sent to the chosen supplier via e-mail, portal, or electronic data interchange.

The supplier accepts, rejects, or negotiates changes. Acceptance makes the document a binding agreement and triggers fulfillment scheduling.

Example of how to dispatch the order and secure supplier confirmation:

Upon finance sign-off, the e-procurement platform transmits the PO simultaneously by EDI and portal notification to the belt manufacturer.

The supplier’s CSR opens the portal, reviews quantity, price, and delivery terms, and clicks “Accept”, a legally binding e-signature that flips the PO status to Confirmed in both systems.

An automated acknowledgement, including the supplier’s planned ship date and tracking-ready ASN number, flows back into the buyer’s ERP, where fulfilment milestones are now visible on a real-time dashboard.

If the supplier needed to adjust lead-time or split the shipment, they could propose a change directly in the portal; built-in rules would route the amendment for buyer approval before acceptance.

This closed-loop confirmation replaces email chains, locks in contractual obligations, and synchronises production scheduling on both sides within minutes.

5. Receive, inspect, and record the delivery

Goods arrive at the dock, or services are rendered. Receiving staff check quantities and condition against the purchase order, flag discrepancies, and enter the receipt into the system so inventory and project teams have real-time visibility.

Example of how to receive, inspect, and record the delivery:

When the conveyor belts reach the plant’s receiving dock, the warehouse clerk scans the advance-shipping-notice (ASN) barcode on the pallet. The handheld device automatically pulls up the matching PO lines and prompts a blind count: two team members tally 12 belts, verify part numbers, and check for surface damage.

One belt has frayed edges, so the clerk logs a discrepancy of “-1” and attaches a smartphone photo as visual evidence. The scan instantly updates the ERP: inventory shows 11 belts available, one belt in a quarantine location, and the PO line status flips to “Partially Received – Exception.”

A goods-receipt note (GRN) is auto-generated and routed to Accounts Payable and Maintenance, giving them real-time visibility. Simultaneously, the buyer receives an alert to initiate a return-material authorisation (RMA) for the damaged unit.

This seamless, scan-to-system workflow records the delivery, protects data accuracy, and triggers next steps without manual spreadsheets or email chains.

6. Match documents and release payment

Accounts payable performs two, three, or four-way matching: purchase order, delivery receipt, supplier invoice, and sometimes contract, to confirm price, quantity, and quality before authorising payment according to agreed terms.

Example of how to match documents and release payment:

Once the supplier’s e-invoice arrives in the AP inbox, an AI-OCR engine extracts header and line-item data and pairs the invoice with the corresponding PO-GRN combo already in the ERP.

The three-way-match bot checks unit price, quantity received (11 accepted belts), tax code, and payment terms (Net 30) in milliseconds; finding no variances greater than the 2 % tolerance, it stamps the invoice “Matched – Ready to Pay.”

An exception queue would have been triggered automatically for any mismatch, routing disputed lines to the buyer and receiver for resolution, but none is needed. The matched invoice posts to the ERP’s payment run schedule, and on the next weekly pay cycle, the system bundles it into an electronic funds transfer batch.

Treasury reviews a consolidated cash-forecast dashboard, approves the batch with a digital signature, and the bank file is transmitted securely via API. The ERP then updates the PO status to “Closed,” records the payment transaction, and archives all linked documents for audit, completing a touchless procure-to-pay loop.

7. Archive, analyse, and continuously improve

Once the transaction is settled, all documents are stored for compliance. Spend data feeds supplier scorecards, inventory optimisation, and budgeting reports, while process metrics expose bottlenecks that can be eliminated through automation and policy tweaks.

Example of how to archive, analyze, and continuously improve:

Immediately after payment is confirmed, the e-procurement suite auto-archives the entire document chain (requisition, PO, ASN, GRN, invoice, and remittance) in a WORM-compliant repository tied to the audit calendar.

A nightly ETL job pipes the transaction’s metadata into a spend analytics cube, refreshing supplier on-time-delivery KPIs and updating the inventory-reorder model with actual lead times. Power BI dashboards flag that belt deliveries average four days faster than contract, prompting the buyer to renegotiate safety-stock levels and free € 12,000 in working capital.

Concurrently, the process-mining module maps each procure-to-pay instance and spots a recurring two-hour delay between GRN entry and invoice posting; a drag-and-drop workflow tweak removes an unnecessary manual validation step, shaving one day off cycle time.

Quarterly, the VRM committee reviews these insights, adjusts approval thresholds, and adds new exception rules, closing the loop between archival, analysis, and continuous policy and automation improvements.

10 Best Practices for Optimizing the Purchase Order Management Process

The following are the best practices to optimize your purchase order management process:

1. Map and simplify every step

Start by sketching the present sequence, from requisition to close-out, and eliminate duplicate reviews, surplus form fields, or approvals that add no control value. A lean flow reduces hand-offs and speeds purchasing without sacrificing oversight.

Example of how to map and simplify the PO management process:

In a Lean Six Sigma project at a large financial data services firm, the team flow charted every touchpoint from requisition submission to PO dispatch and discovered that manual queue assignment, an extra handoff with no added control, was the main bottleneck.

By automating that routing step and eliminating other low-value approvals, the company slashed average PO cycle time from seven days to two and reduced staffing for issuance from nineteen to just two full-time employees, all while boosting purchase order throughput and freeing buyers for more strategic tasks.

2. Codify clear policies, limits, and approval thresholds

Write down who may raise a purchase order, at what spend limits extra sign-off is required, and how preferred suppliers or contract terms must be applied. Baking these rules into the digital workflow keeps decisions consistent and audit-ready.

Example of how to codify clear policies, limits, and approval thresholds:

At a global consumer electronics group, procurement partnered with finance to codify a new authority matrix for every purchase order. They documented which roles could create requests, set clear spend thresholds, and linked preferred supplier lists to commodity codes.

When the rules were embedded in the cloud purchasing system, the platform enforced them automatically: requisitions under five hundred euros were auto-approved at the department level, those between five hundred and ten thousand euros were routed to the budget owner, and higher amounts went straight to the chief financial officer.

Within three months, compliance with preferred supplier contracts rose from sixty-eight percent to ninety five, audit exceptions fell by half, and cycle times shortened because buyers no longer chased signatures.

3. Digitize and automate the workflow

Move away from paper and e-mail chains to an integrated procure-to-pay platform that auto-routes approvals, auto-populates line details, and timestamps every action. Automation trims human error and lets teams focus on higher-value analysis.

Example of how to digitize and automate the workflow:

During a company-wide digital overhaul at a mid-size pharmaceutical manufacturer, procurement replaced paper forms and scattered email approvals with an integrated procure-to-pay platform.

The system drew item data directly from master files, pre-filled quantities and prices, routed each request along a rules-based path, and time-stamped every click for audit traceability.

Automating these steps cut manual entry errors by seventy percent, reduced average approval time from four days to less than one, and freed buyers to spend almost half of their week on supplier development and savings analysis instead of chasing paperwork.

4. Keep a single, centralized source of truth

Maintain all purchase-order data, supplier records, receipts, and invoices in one system so stakeholders see the same live information. Centralization boosts visibility, speeds reconciliation, and supports accurate spend analytics.

Example of how to keep a single, centralized source of truth:

At a national logistics firm, procurement and accounts payable migrated decades of fragmented supplier files, purchase orders, goods receipts, and invoices into one cloud database.

With every record tied to a common supplier ID and purchase order number, buyers, warehouse staff, and finance teams accessed live status updates from the same dashboard.

The shared ledger cut reconciliation time per month end close from nine days to three, dropped duplicate payment incidents to near zero, and enabled spend analysts to build accurate category reports in hours instead of weeks.

5. Secure two-way confirmation and real-time tracking

Send the approved order to the supplier for acknowledgement, capture their confirmation inside the platform, and display live status updates, from dispatch to delivery inspection, so buyers, receivers, and finance act on the latest facts.

Example of how to secure two-way confirmation and real-time tracking:

At an international food retailer, procurement enabled two-way order confirmation by linking its purchase system with suppliers through a secure portal.

Each approved order arrived instantly in the vendor dashboard, the supplier clicked accept or proposed changes, and the system logged that response while launching real-time status feeds that tracked packing, shipment, arrival, and quality inspection.

With every step visible to buyers, warehouse receivers, and finance, on-time delivery rose from eighty-two percent to ninety six in six months, invoice match exceptions fell by one-third, and the team eliminated countless update emails that once clogged inboxes.

6. Measure performance with well-defined indicators

Track cycle time, first-pass match rate, on-time delivery, price variance, and other key metrics. Regularly review the data to flag bottlenecks and guide targeted process tweaks.

Example of how to measure performance with well-defined indicators:

In a data-driven overhaul at a leading consumer goods distributor, procurement integrated its purchase order system with business intelligence software to collect cycle time, first pass invoice match rate, on-time delivery performance, price variance against contract, and other key performance indicators in a live dashboard.

Weekly review meetings revealed that purchase orders for indirect materials suffered the longest cycle time because of redundant quality checks, while the first pass match rate lagged because incomplete goods receipts delayed invoice matching.

By tightening the receipt process and removing the duplicate inspection, the team cut average cycle time from six days to two, lifted first pass match rate from seventy-three percent to ninety two, and saved more than one hundred fifty thousand euros in late payment penalties over a quarter.

7. Strengthen supplier collaboration

Use shared portals or automated notifications to keep vendors informed, resolve discrepancies quickly, and capture their feedback. Transparent communication improves fulfillment accuracy and deepens trust.

Example of how to strengthen supplier collaboration:

At a multinational apparel brand, procurement rolled out a supplier collaboration portal that let vendors view purchase order status, upload shipping notices, open disputes, and share performance feedback in real time.

Automatic notifications alerted suppliers whenever forecasts changed or documentation was missing, while a shared chat thread kept every exchange tied to the relevant order.

Over the next season, fulfillment accuracy climbed from ninety percent to ninety eight, average dispute resolution time dropped from eight days to fewer than two, and supplier satisfaction scores rose by fifteen points, proving the value of transparent communication and quick issue resolution.

8. Revisit fundamentals and train users continually

Even mature teams benefit from refresher sessions on raising accurate purchase orders, choosing the right order type, and updating master data. Well-trained users create cleaner transactions that flow through the process without rework.

Example of how to revisit fundamentals and train users continually:

At a regional healthcare network, procurement launched quarterly refresher workshops and short e-learning modules covering purchase-order accuracy, selecting the correct order type, and keeping item and supplier master data current.

New hires completed the modules during onboarding, while seasoned staff attended live sessions that walked through real error cases and updated policy changes.

Within two quarters, data-entry mistakes on purchase orders fell by sixty percent, invoice holds triggered by incorrect master data dropped by half, and overall cycle time shortened because transactions flowed straight through the system without rework.

9. Embed compliance and legal safeguards

Configure mandatory fields for contract references, price caps, and jurisdiction clauses, and trigger alerts when orders exceed policy limits or risk scores. Proactive controls avert costly disputes and regulatory exposure.

Example of how to embed compliance and legal safeguards:

At a global construction equipment manufacturer, procurement partnered with legal and risk teams to embed mandatory compliance checkpoints in the cloud purchasing platform.

Every purchase order now carries a contract reference, a price ceiling, a governing law clause, and a supplier risk score. If a buyer tries to exceed the ceiling by more than five percent or chooses a governing law that is not preferred, the system blocks submission and sends an alert to legal counsel.

Within six months, policy violations fell from one hundred forty to eleven, external legal review fees dropped by thirty percent, and regulators closed the annual audit with zero findings.

10. Commit to continuous improvement

Schedule periodic reviews of cycle metrics, exception logs, and stakeholder feedback. Use the insights to fine-tune thresholds, update guidance, and automate new pain points, turning purchase-order management into a living, ever-better system.

Example of how to commit to continuous improvement:

At a multinational automotive supplier, procurement set up a monthly continuous-improvement board that reviews cycle-time dashboards, exception logs, supplier complaints, and feedback from finance and receiving.

Each meeting assigns owners to the top three pain points and agrees on quick experiments—adjusting approval thresholds, adding a receipt reminder, or automating a new exception rule.

Results are checked at the next session, successful tweaks are rolled into a standard workflow, and lessons are documented in an online playbook.

Over a year, the iterative cycle shaved purchase order lead time by forty percent, cut invoice exceptions by half, and generated a rolling backlog of small wins that keep the process evolving instead of slipping back into old habits.

Conclusion

Purchase order management combines a clear, end-to-end process (from requisition through receipt and matching) with defined controls and digital tools to make every purchase legally binding, transparent, and aligned with budget.

This gives the company full cost visibility, reinforces accountability across all parties, and lowers the risk of delays, overruns, and disputes. Moreover, a standardized, digitized workflow produces rich data that powers advanced analytics and continuous improvement of procurement performance.

Frequentlyasked questions

What is purchase order management?

Purchase order management is a controlled, digital workflow that turns requisitions into legally binding, budget-aligned orders and tracks them through receipt and matching.

What is the most important type of purchase order?

The standard purchase order sets the template for a single, fully specified buy and underpins all other purchase order variants.

Can you describe one of the best practices in order management?

Digitize the entire purchase order lifecycle in an e-procurement platform to cut errors, gain real-time visibility, and feed analytics for continuous improvement.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.