Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

Sole Sourcing vs Single Sourcing — 6 Crucial Differences

As taught in the Supplier Relationship Management Course / ★★★★★ 4.9 rating

What is the difference between sole sourcing and single sourcing?

- Single sourcing involves choosing from several potential suppliers but choosing only one that meets your needs.

- Sole sourcing is having only one supplier to meet your needs.

- Single sourcing provides more flexibility and resilience than sole sourcing.

Hey, we know what you want. You are here to know the difference between sole sourcing vs. single sourcing. Do not worry, we are here to help you.

We will give the key differences between sole sourcing and single sourcing that we will discuss further in this article.

The procurement department has a lot of ways to acquire the goods or services that it needs to operate. It is crucial for them to find the right suppliers in order to have an effective supply chain. But sometimes, using sole sourcing or single sourcing is necessary for the procurement process.

What is Sourcing?

Before we tackle sole sourcing and single sourcing, we must first know what sourcing means. The sourcing process includes every process that revolves around identifying and evaluating potential suppliers, as well as choosing a supplier that can give the best value for a company.

To simplify, sourcing is about knowing the most suitable supplier that can provide the needs of a company as well as give them advantages against other competitors.

What is Sole Sourcing?

Sole sourcing pertains to a situation when there is only a single supplier that provides the product or service that you need. These are the types of products or services that are unique and can only be found through a single supplier. The business has no other choice.

Sole suppliers are usually those who manufacture specialized parts or are the only ones left selling outdated material. In some instances, businesses choose sole sourcing because it is the only supplier that can handle their requirements.

Click here for in-depth learning of sole sourcing and how it is done.

What is Single Sourcing?

Single sourcing refers to purchases when there is more than one supplier who provides the product or services that you need. The company selects only one among the suppliers who can provide what they need. For example, if your company chooses to buy Samsung laptops instead of any other brands that also sell laptops, then that is single-sourcing.

The company may choose based on what it thinks it needs. It may select the other due to the difference in prices. The company may also choose based on the quality of materials the supplier provides.

The 6 Key Differences Between Sole Sourcing and Single Sourcing

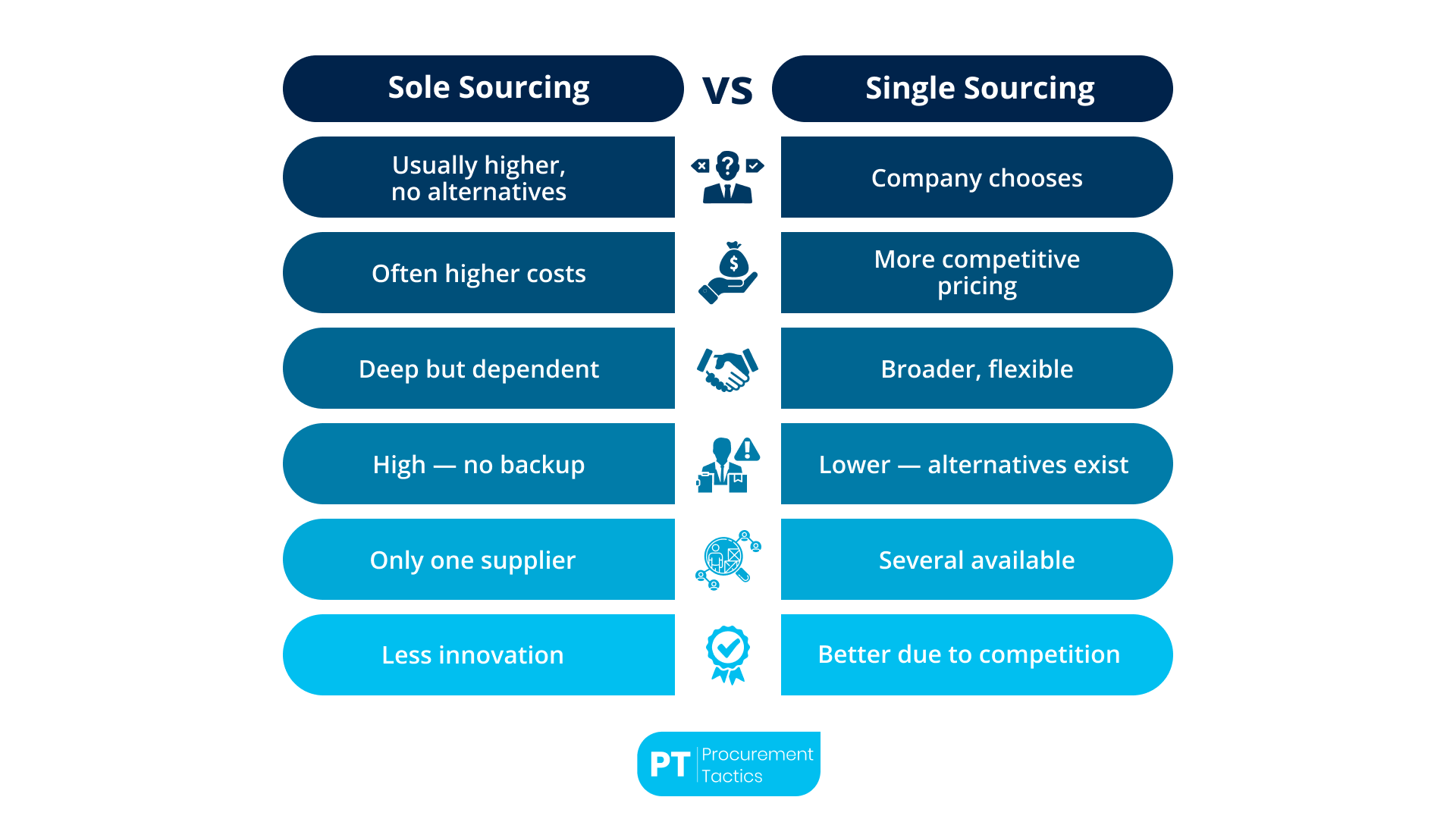

1. The Power to Decide

The power to choose in sole sourcing is with the supplier. In this case, the supplier has the freedom to demand the terms. This is due to the fact that only the supplier can provide what the company needs.

On the other hand, the power to decide lies to the company when we talk about single sourcing. The company has the decision whether they will select the supplier base on the terms that they want.

2. Costs

In sole sourcing, the absence of alternative options may lead to potentially higher costs for whatever the company will procure.

On the other hand, in single sourcing, the company has the ability to engage with multiple suppliers. Thus, securing more favorable prices for what the company wants to buy.

3. Supplier Relationship

Companies can develop a deeper relationship in sole sourcing, especially since your supplier is your main “go-to” place when you need something.

On the other hand, in single sourcing, the company can have a diverse network of relationships with its suppliers. Although these connections may not be that deep, it is still valuable to the company, especially when it comes to win-win situations.

4. Risks

Sole sourcing can give you more risks as you do not have any alternative when your supplier fails to meet your requirements.

On the other hand, with single sourcing, you can explore other establishments if your primary choice cannot meet your requirements. Thus, this approach diversifies or spreads the risks, decreasing the chance of incurring a great loss.

5. Supplier Options

With single sourcing, you can have many alternatives for the goods or services that you need. Thus, the freedom to choose whom you want to negotiate with.

On the other hand, sole sourcing only allows you to depend on a single supplier because that supplier is the only one who can provide the goods or services that you need.

6. Quality

When you go with single sourcing, suppliers realize they need to stand out to get picked by you. So, they work harder to give you good choices. They want to impress you.

But in sole sourcing, the supplier knows they’re the only option. So, they might not feel the need to come up with new or cool stuff. You might end up getting the same thing over and over without any exciting changes.

Pro Tip: Always evaluate whether you’re in a sole sourcing situation by necessity—or by habit. Many companies unknowingly fall into sole sourcing because “that’s how it’s always been done.”

⭢ Regular supplier audits, market scans, and category reviews, as taught in our Supplier Relationship Management Course, can reveal overlooked alternatives and reduce your dependency risk.

Advantages and Disadvantages of Single Sourcing

As procurement manager within the largest retailer in the Netherlands, I have often consciously and unconsciously opted for single sourcing.

I can’t think of any examples of sole sourcing, as within the FMCG sector, there were always multiple suppliers within a category.

However, I have experienced the disadvantages of single-sourcing in various cases. For example, a major supplier had a factory fire, which meant we had no inventory for a longer period.

This led me to always choose multiple suppliers for the most important items (in private label). Albert Heijn uses various distribution centers.

I made contracts for my key products per distribution center and ensured that there were at least 2 different suppliers for these items.

If, for any reason, one supplier couldn’t deliver, we could easily switch to the other suppliers. This prevented prolonged Out of Stocks.

Therefore, my advice is to be conscious of the strategy of single sourcing versus multiple sourcing.

Single sourcing has many advantages, but the question is whether they outweigh the potential risks.

Real Life Example of Single Sourcing

In 2019, Bad Robot signed a five-year, $250 million+ deal with WarnerMedia for exclusive content across film, television, and gaming. This allowed Bad Robot to focus on production while WarnerMedia leveraged its extensive network (HBO, HBO Max) for distribution and marketing, gaining a competitive edge in the streaming market by securing high-profile content from J.J. Abrams. This demonstrates the benefits of specialized roles within a supply chain, where each partner focuses on its core strengths.

Advantages and Disadvantages of Sole Sourcing

Real Life Example of Sole Sourcing

Taiwan Semiconductor Manufacturing Company (TSMC) is a dominant player in the semiconductor industry, controlling a significant portion of the global foundry market, with estimates ranging from 55% to 64%. Notably, TSMC manufactures approximately 90% of the world’s leading-edge semiconductors, which is critical for advanced technologies. This dominance has led major tech companies to rely solely on TSMC, recognizing their unmatched capabilities, a situation some describe as a “manufacturing monopoly,” highlighting TSMC’s critical role in the global semiconductor supply chain.

Procurement Expert’s Advice on Sole Sourcing vs Single Sourcing

For this article, we asked an experienced procurement expert to share her insights to help answer common questions about sole sourcing and single sourcing.

Nesrin Chabbah

Senior Lead Buyer

LinkedIn Profile: linkedin.com/in/nesrin-chabbeh

1. What do most people get wrong about sole sourcing and single sourcing?

“A prevalent misunderstanding is that sole sourcing is invariably a suboptimal option. However, it can be essential for distinctive products or services, especially when partnering with a pioneering or leading supplier in a particular field.

Sole sourcing makes sense when there’s exclusivity for a range of products. Ultimately, the choice between sole and single sourcing hinges on the specific context and requirements.”

2. What should people know about sole sourcing and single sourcing if they are planning to start working on these?

“When planning to work on procurement or sourcing decisions, particularly concerning sole sourcing vs. single sourcing, it’s essential to consider the uniqueness of the product or service and whether a single supplier is the only option.

Evaluate supplier options and conduct cost-benefit analyses to determine which approach is more cost-effective. Assess risks associated with each method and consider the impact on supplier relationships and product quality.

Flexibility and continuous monitoring of supplier performance are crucial, as is compliance with relevant regulations. Consulting experts in procurement can provide valuable insights to inform decision-making.”

3. From your experience, what is the most important thing you learned about sole sourcing and single sourcing?

“A prevalent misunderstanding is that sole sourcing is invariably a suboptimal option. However, it can be essential for distinctive products or services, especially when partnering with a pioneering or leading supplier in a particular field.

Sole sourcing makes sense when there’s exclusivity for a range of products. Ultimately, the choice between sole and single sourcing hinges on the specific context and requirements.”

4. What tips can you give them about sole sourcing and single sourcing?

“Effective procurement and sourcing decisions, whether involving the choice between sole sourcing and single sourcing or other aspects, benefit from several essential tips. It all begins with a detailed analysis of your distinct requirements and the available market options.

Conducting a comprehensive cost-benefit assessment is crucial to comprehend the financial implications over time, while also carefully evaluating associated risks.

Cultivating strong relationships with suppliers is imperative, and flexibility in response to shifts in market conditions or supplier performance is key.

Always ensure compliance with pertinent laws and regulations, maintain meticulous documentation, and don’t hesitate to seek expert guidance when needed.

These guidelines, when tailored to your organization’s unique circumstances, empower you to make well-informed decisions that enhance overall procurement management.”

5. Can you give us an example of how you do sole sourcing and single sourcing at your work?

“Implementing sole sourcing requires a solid contract to mitigate risks, particularly in times of price volatility, raw material shortages, and market competition.

It’s essential to seek and test smaller suppliers, partnering with them for specific products and small quantities to assess their performance.

This preparation helps in managing potential challenges arising from sole sourcing effectively. In the case of single sourcing, maintaining one to three alternative suppliers proves crucial.

This approach became evident during the Covid Crisis when we needed to restrict purchases and seek local solutions, emphasizing the importance of having backup suppliers.”

Conclusion

We now know the definitions of sole sourcing and single sourcing and explore their differences. In this article, we also explored its advantages and disadvantages. We compared sole sourcing vs. single sourcing to see what is more efficient to do.

Sole sourcing vs. single sourcing’s main similarity and difference is choice. Both processes have a choice, but the difference is where the favorable outcome lies. Sole sourcing is mostly favorable for the company, and single sourcing is beneficial for the supplier.

Nevertheless, sole sourcing vs. single sourcing has its own advantages and disadvantages. It is at the company’s discretion to choose which of the processes it may need.

If it requires an item that only one supplier provides, then it sticks with the sole sourcing. On the other hand, if many are providing the same goods or services, then it will select the best match for its needs.

Frequentlyasked questions

What is the main difference between sole sourcing and single sourcing?

Single sourcing and sole sourcing both mean purchasing from one supplier. The difference is that in single sourcing, it’s a choice where, for example, you buy from one supplier for efficiency reasons, while in sole sourcing, there is only one supplier that can provide the product.

What is sole sourcing?

Sole sourcing pertains to a situation when there is only a single supplier that provides the product or service that you need.

What is single sourcing?

Single sourcing refers to purchases when there is more than one supplier who provides the product or services that you need.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.

Popular Procurement Courses

At Procurement Tactics, we educate Procurement Professionals to close better deals, secure supply and advance their career. Our courses are online and self-paced.

Negotiation Course for Procurement

Learn from industry experts who negotiated billion $ deals

Artificial Intelligence in Procurement Course

Unleash the power of artificial intelligence within procurement

AI Implementation Course for Procurement Leaders

Lead the AI shift with confidence in procurement

Related Articles

Human-AI Balance in Procurement — Striking A Balance

Written by Marijn Overvest | Reviewed by Sjoed Goedhart | Fact Checked by Ruud Emonds | Our editorial policyHuman-AI Balance in Procurement — Striking A BalanceAs taught in the Artificial Intelligence in Procurement Course / ★★★★★ 4.9 ratingTable of contents AI in...

Generative AI in Procurement — 5 Use Cases + 10 Emerging Trends

Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policyGenerative AI in Procurement — 5 Use Cases + 10 Emerging TrendsAs taught in the Artificial Intelligence in Procurement Course / ★★★★★ 4.9 ratingTable of...

Managing Gen Z Talent: Future-Proofing Procurement Teams

Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policyManaging Gen Z Talent: Future-Proofing Procurement TeamsAs taught in the Gen Z & Generational Management in Procurement / ★★★★★ 4.9 ratingTable of contents...