Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

Strategic Procurement — Explained + Process

As taught in the Strategic Procurement Leadership Program / ★★★★★ 4.9 rating

Table of contents

- Strategic Procurement

- Strategic Procurement Process

- Procurement Vs. Sourcing Vs. Supply Chain Management

- Strategic Procurement Objectives

- Importance of Strategic Procurement

- Benefits of a Strategic Procurement Plan

- Examples of Strategic Procurement

- Procurement Expert’s Advice

- Conclusion

- Frequently asked questions

What is strategic procurement?

- Strategic procurement is the process of acquiring goods/services of the right quality, at the right price, and at the right time to meet customer demand.

- Strategic procurement focuses on buying goods or services to meet customer demand while following long-term organizational goals.

- This process highlights cost reduction and optimal use of purchasing power without compromising quality.

What is Strategic Procurement?

Strategic procurement is the process of buying goods or services that meet specific quality, cost, and timing goals. It supports long-term business plans and helps companies use resources wisely.

This process involves more than one team. While procurement leads the effort, other departments also help shape the strategy. The goal is to reduce costs, limit risks, and improve how the company works with suppliers.

Data plays a key role. Companies use spending data, supplier records, and market trends to make smart choices. With the right information, they can secure better deals and avoid problems.

Strategic procurement is especially useful in global markets. It helps companies stay efficient, even when supply or pricing shifts.

Some people confuse it with strategic sourcing or supply chain management. While related, each serves a different purpose. Procurement handles what to buy and how to buy it. Sourcing finds suppliers. Supply chain management moves goods through the system.

By focusing on long-term value instead of short-term gains, strategic procurement helps companies save money, build strong supplier partnerships, and stay competitive.

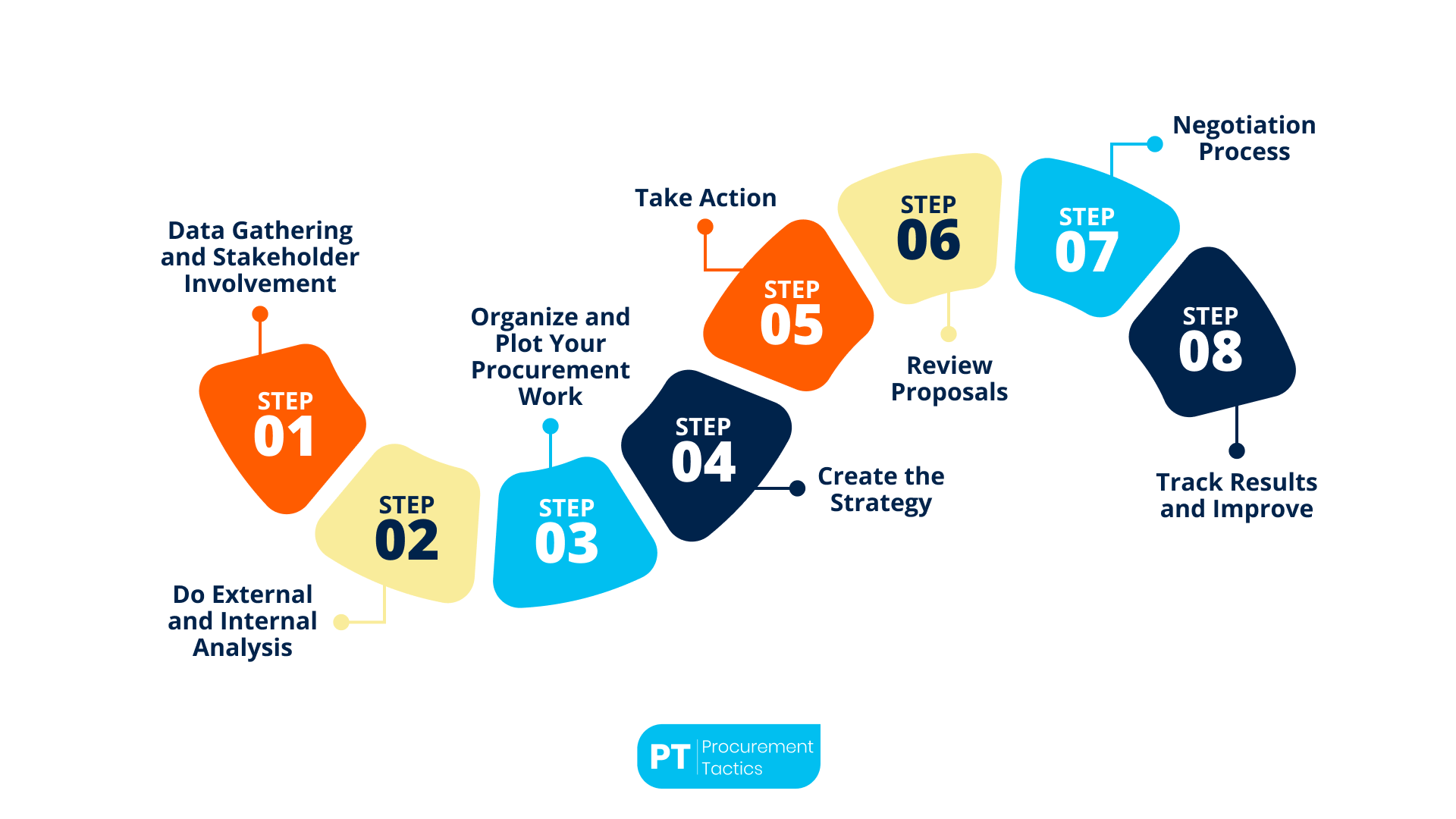

Strategic Procurement Process

The strategic procurement process varies from company to company, but here’s a general outline of what you can expect from one.

1. Data Gathering and Stakeholder Involvement

One way or another or every company starts with data gathering. Collect spending data, supplier information, and contract details.

Make sure the information is current and reliable. At the same time, talk to key people inside the company.

This includes your sales team, finance team, and other business units. Their input helps you understand needs and set direction. This step builds support and gives you insight before you begin planning.

2. Do External and Internal Analysis

Once you have the data, analyze the external environment using the PESTEL model. This includes political rules, economic trends, social behavior, technological changes, environmental concerns, and legal requirements. These factors affect supply options, pricing, and risks.

Next, analyze your internal situation. Look at spending habits, supplier performance, and team capacity. Internal analysis helps you know what is working and what is not.

Together, these two views help you decide what kind of procurement strategy your company needs.

3. Organize and Plot Your Procurement Work

Now, group and structure the data. Use tools like stakeholder maps and supplier segmentation. This helps you set focus points.

This is called procurement plotting. It helps you divide suppliers and categories into groups. You can then decide how much time and effort to invest in each one.

This step helps you set clear priorities.

4. Create the Strategy

Use what you have learned to write the strategy. It should reflect your company’s business goals.

A good procurement strategy includes clear objectives, deadlines, and performance metrics. It should also allow for change when needed.

Company goals should be connected to procurement goals. For example, if your company wants to grow, your strategy may focus on building new supplier relationships or increasing supply reliability.

5. Take Action

Now put the strategy into motion. Take the steps needed to apply your plan in practice. Launch the sourcing process. Review suppliers. Check what your organization needs and what each supplier offers.

See if the partnership is a good fit. Prepare communication plans. Assign tasks to the right people. Make sure everyone understands their role. This stage turns planning into real action.

Action is where plans become results.

6. Review Proposals

Once you collect supplier proposals, compare them. Do not focus on price alone. Look at delivery terms, service levels, payment terms, and quality history.

Pick the supplier that fits the strategy. Then, begin contract talks. Set terms clearly. Include service rules, penalties, and review dates.

This step protects your company and helps the supplier deliver.

7. Negotiation Process

Now it’s time to look at bids. You look through all the bidders and select from a pool of your most comprehensive propositions. You may also pick out the most appropriate bidder and the second most successful bidder.

After every bid and vendor has been reviewed and upheld to your strategic procurement criteria then contractual talks can be initiated with the winner.

8. Track Results and Improve

Procurement is not a one-time task. It is an ongoing cycle.

Track results with supplier scorecards and regular meetings. Check for missed targets or risks. Update the strategy if goals or business needs change.

The value of continuous improvement is clear. Teams should look for small changes that improve service, reduce costs, or lower risks.

Good procurement professionals use data and feedback to adjust the strategy year after year.

Procurement vs. Sourcing vs. Supply Chain Management

Strategic sourcing and supply chain management come up at least half the time that strategic procurement is mentioned. Some people even use them interchangeably, but it’s important to know that there are distinctions between them and also to know what these distinctions are.

The most important thing to note before we differentiate is that procurement is an umbrella term that encompasses sourcing and supply chain management. However, these terminologies should not be interchangeable since they all have different functions within the overall procurement process.

Though both exist within the same process continuum they have different strategies, dynamics, and implementations at play. This can be seen clearly by the differing KPIs (key performance indicators) of each one. To illustrate this further, take a look at the table below where we show some KPIs of each.

Strategic Procurement Objectives

Strategic procurement helps organizations plan and control how they buy goods and services. It supports long-term goals by focusing on value, efficiency, and stability. Below are the main objectives:

1. Reduce Costs and Increase Value

Strategic procurement aims to reduce costs across the full product or service life cycle. This includes purchase price, maintenance, and disposal. It uses data to find savings, improve processes, and get better supplier terms.

2. Control Risk and Ensure Supply

Risk factors like supplier failure or delivery delays are identified early. Backup plans are created to keep materials and services flowing without disruption.

3. Build Strong Supplier Relationships

Companies work to maintain long-term partnerships based on trust and clear communication. Strong relationships lead to better service, stable pricing, and higher reliability.

4. Support Innovation and Improvement

Suppliers are encouraged to suggest new ideas. Procurement teams track performance and apply feedback regularly to improve results and processes.

5. Follow Sustainability Goals

Purchases reflect company standards for environmental impact and social responsibility. Suppliers are chosen based on ethical practices, safe materials, and legal compliance.

6. Meet Legal and Policy Rules

Clear guidelines are used to ensure all actions follow laws and internal policies. Regular checks help reduce legal risks and support accountability.

The table shows different sets of KPIs which is a clear indication of the differences in functionality of each. So let’s break it down.

Supply Chain Management

As the name suggests, supply chain management oversees and manages the supply chain. White procurement gets the goods, and supply chain management is in charge of getting those goods to the organization.

It involves the entire network of stakeholders involved in getting the product into the hands of the customer. From gathering the raw materials, through to manufacturing, transportation, warehousing, processing, and through to the end-user.

Ultimately supply chain management should still fall under the responsibility of the procurement department.

Procurement

Procurement refers to the process of acquiring goods and services needed for the organization’s business model. It typically stops the moment the organization has those goods and services.

Sourcing

Sourcing is all about finding sources of goods and services needed by the company. Sourcing is solely focused on finding the best and most cost-effective suppliers of goods and services, as opposed to the broader reach of procurement’s whole process of the acquisition of those materials and the logistics of that.

Sourcing is concerned with finding quality goods and services from suppliers who are aligned with the company’s goals and morals, all at the best price. It may seem like sourcing is a one-time thing but it’s a constant maintenance of supplier relationships, quality, and cost.

Hopefully, the differences between supply chain management, procurement, and sourcing were explained enough here.

Importance of Strategic Procurement

Why is strategic procurement important? The biggest reason why is because it works. Business is always a gamble, especially because there are so many ways that it can be handled. However, certain systems and processes have been set up over many years to ensure that a business can be successful.

Strategic procurement is a trusted and tried method. As much as innovation and creativity are needed to run a good and successful business, certain processes remain the same for a reason. Strategic procurement is one of these.

Having a data-driven process for the efficient handling of the procurement process is a no-brainer. This system was made for the efficiency of a complex web of systems that work together as one. As an organization, there is no question about the importance of something so integral to the efficiency of a business.

Benefits of a Strategic Procurement Plan

Here are some benefits of a strategic procurement plan that you should know about!

1. Standardization and Streamlining

Strategic procurement is all about analysis and optimization. Doing this means having to standardize and streamline. Standardization of procedures is a must, and having it go hand in hand with leveraging technology and implementing best practices keeps an organization on top of its game.

Due to strategic procurement organizations can easily streamline the procurement process as there’s little resistance to overall process effectiveness.

2. Visibility

It always helps to have visibility in any aspect of procurement. Having a solid procurement strategy means organizations gain better visibility into their spending and can identify the areas in which they can be more efficient with their spending.

3. Cost-Efficiency

A very important part of strategic procurement is the identification of cost-saving opportunities. These opportunities can be found or made through negotiations, volume discounts, supplier consolidation, and process efficiencies.

4. Risk Management

There are many risks in the supply chain and as time goes on new risks are introduced day by day. However, having a robust procurement strategy helps swat away the risks and ensures little chance of them disrupting the flow of operations in your organization.

5. Good Supplier Relationship

Strategic procurement makes sure that supplier relationships are good and mutually beneficial. Strong relationships are built with key suppliers, collaborative partnerships, and open communication.

This ensures that suppliers are more likely to deliver their best and more to your organization. A good relationship keeps everyone happy and mutually productive in their partnership.

6. Quality Goods and Services

Strategic procurement allows organizations to scrutinize their supplier’s capabilities, track record, and commitment to quality. This gives them better opportunities to access high-quality goods and services. As we’ve established that their supplier relationship is also well maintained, suppliers are also more likely to provide innovative solutions and more readily collaborate on improving processes and products.

These are only some of the benefits of a good procurement strategy. Overall, it would improve the quality of life of any organization and keep said organization efficiently run and well maintained.

Examples of Strategic Procurement

Here are some examples of strategic procurement that you may want to know about. These examples are derived from companies that are pioneers in their field because of their strategic procurement.

1. Walmart

The Case:

Walmart sought to reduce costs and improve supply chain efficiency by transforming its sourcing strategy.

Strategic Solution They Have Taken:

Walmart implemented a direct sourcing approach, increasing direct purchases from 20% to 80%, which led to 5–15% cost savings and reduced procurement time. The company established centralized procurement centers in regions like Mexico and Canada, enabling better coordination and standardized quality control.

Additionally, Walmart formed strategic vendor partnerships, offering long-term, high-volume contracts in exchange for lower prices. This approach secured consistent product quality, ensured a steady supply of goods, and strengthened its competitive edge.

2. Procter & Gamble (P&G)

The Case:

P&G integrated strategic sourcing into its core business operations to strengthen its global market position and drive innovation.

Strategic Solution They Have Taken:

The company developed a Supplier Relationship Management (SRM) program that fosters close collaboration with suppliers. This program reduces costs, improves product quality, and drives innovation at a global scale.

P&G also emphasizes sustainability, working hand-in-hand with suppliers to minimize environmental impact. Moreover, the company upholds strong commitments to social responsibility across its supply chain. By prioritizing innovation, sustainability, and collaboration, P&G consistently delivers high-quality products while maintaining responsible business practices.

3. Apple Inc.

The Case:

Apple Inc. aims to stay at the forefront of the tech industry through innovation, high design standards, and ethical sourcing practices.

Strategic Solution They Have Taken:

Apple sources cutting-edge technologies and materials that enhance product design and performance. The company collaborates closely with suppliers to maintain its aesthetic and functional standards.

Apple also enforces its Apple Supplier Code of Conduct, ensuring suppliers uphold strict ethical and operational standards through regular audits. Additionally, Apple promotes diversity in its supply chain by partnering with minority-owned businesses.

By focusing on innovation, design, and social responsibility, Apple secures its position as a global leader while producing technologically advanced and ethically manufactured products.

Procurement Expert’s Advice on Strategic Procurement

For this article, we asked a seasoned procurement professional to share his insights regarding strategic procurement.

Sjoerd Goedhart

Owner, Goedhart Interim Management & Consultancy

LinkedIn Profile: https://www.linkedin.com/in/sjoerdgoedhart/

1. Can you share a personal example of strategic procurement? What can readers learn from this?

“During the COVID-19 pandemic and the Ukraine crisis, companies with robust strategic procurement practices experienced significantly less impact. Those who had implemented effective strategic procurement processes and utilized advanced technologies were able to mitigate risks and maintain better availability of goods. Consequently, they gained a competitive advantage in the market. This highlights the importance of strategic procurement in navigating challenging times, enabling businesses to adapt and thrive in volatile environments.”

Follow-up Question: How did these companies ensure the implementation of a strategic procurement method? What challenges did they face during times of crisis?

“To implement a strategic procurement method, companies need to prioritize it on the management agenda and integrate it into overall risk management. This involves identifying weaknesses, formulating plans to address them, and having a proactive management team. Regardless of company size, risk management is crucial, and even startups should consider potential risks and adapt accordingly.“

2. What should readers know about strategic procurement?

“Strategic procurement is essential when doing business around the globe. It contains different procurement processes to support the long-term strategy and development of a company.“

Follow-up Question: What is the difference between strategic procurement and the traditional procurement process?

“The key distinction lies between strategic procurement and short-term procurement. Some companies incorporate strategic elements into traditional processes. Modern companies often leverage AI and data, while traditional ones may not. Comparing strategic and short-term procurement provides a more relevant comparison.”

3. What are the essential elements of a comprehensive procurement plan?

“A comprehensive procurement plan begins with a clear understanding of the company’s strategic objectives and adapts to changing business goals. Set and review procurement KPIs to ensure that they are not only a procurement goal, but an organizational goal as well.“

4. To what extent should stakeholders be involved in the development of the procurement plan?

“Stakeholders should be involved in developing the procurement plan to a strategic extent when the initiative spans more than one year.“

5. When should procurement professionals take into consideration when making a procurement plan?

“Procurement professionals should consider category management as a key element in developing a good strategic procurement process.“

Conclusion

Strategic procurement is a key player in an organization’s success because it saves time and effort while keeping everything in check and efficient. It minimizes both cost and risk and keeps organizations prepared for the future.

Strategic procurement is a long-term organizational investment in the maintenance and management of an organization’s partnerships with suppliers. This ensures quality goods and services at a cost-effective rate.

So if you haven’t already, this is your sign to invest in strategic procurement. Save the time, energy, and money of your organization by befriending the strategic procurement process to keep your procurement needs efficiently satisfied.

Now that you’re done reading this article, I have created a free-to-download editable procurement strategy template. It’s a PowerPoint file you can use to create your own strategy. I even created a video where I’ll explain how you can use this template.

Frequentlyasked questions

What is strategic procurement?

Strategic procurement is the process of acquiring goods or services of the right quality, at the right price, and at the right time to meet customer demand.

Why is strategic procurement important?

It helps reduce costs, manage risks, and align everything with organizational goals.

What is the difference between procurement, sourcing, and supply chain management?

Procurement is acquiring goods, sourcing is finding suppliers, and supply chain management is overseeing the entire supply chain process.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.