Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

Supplier Risk Management Framework: A Step-by-Step Guide

As taught in the Risk Management in Procurement Course / ★★★★★ 4.9 rating

Key takeaways

- The supplier risk management framework is a guideline used to identify and mitigate supplier-related risks in their supply chain.

- SRM framework helps companies avoid significant issues that could negatively impact their operations.

- The most effective way to manage supplier risks is through strong supplier relationship management.

Supplier risk management framework allows companies to avoid issues that can severely affect them in the long run. A risk model, especially when sourcing for suppliers, can help companies find a partner that suits and complements their process. The problem is that many people don’t know how to create their own framework to manage supplier risks.

In this article, I will explain what a supplier risk management framework is. I will also discuss the supplier risks you may encounter if you manage them poorly.

After I discuss all the risks you may encounter, I will teach you the step-by-step process of creating a framework for supplier risk management.

This step-by-step process that I will share with you is one that I have formulated throughout the years that I have been teaching procurement to all my students, be they new or seasoned professionals in the field of procurement.

Furthermore, after reading this article, you will be able to create a framework that will allow you to protect you from all supplier risks. So, without further ado, let’s now start!

What is the Supplier Risk Management Framework?

Try searching on Google for the top five supply chain risks, and you’ll often see that supplier management is in every article.

This is not a surprise because all the products businesses sell to consumers are sourced from suppliers. Therefore, risks regarding suppliers are crucial to know if your entire supply chain workflow runs smoothly.

Let’s now talk about the supplier risk management framework. The framework is a guideline used to identify and mitigate supplier-related risks in their supply chain. You can think of it as a guide on how you should act to address and decrease the chances of supplier risks in your supply chain.

The supplier risk management framework offers a high level of control and helps businesses maximize value by offering a more reliable and consistent process for managing supplier risk.

Furthermore, this framework reduces costs through centralized contract management and ensures products arrive on time to improve customer satisfaction.

Potential Risks of Ineffective Supplier Management

These are some of the potential risks that poorly managed supplier risks can expose your company to:

1. Resilience Risk

This risk may come from an issue where a supplier’s failure may delay the process resulting in the interruption of customer service.

An example of this risk is when a supplier cannot deliver raw materials to you due to a geopolitical crisis in their country. Although the problem is valid, it will still lead to production delays that can affect your ability to meet customer demands.

2. Regulatory Risk

This risk comes from the supplier’s failure to comply with regulatory requirements or the undertakings associated with sourcing arrangements.

For instance, a supplier in a different country fails to comply with strict environmental laws, leading to legal penalties and the closure of your supplier’s business. When this happens, it not only delays your production but can also affect your reputation.

3. Information Security and Privacy

This risk involves compromise or leakage of sensitive data, such as customer information, due to a cybersecurity breach or failure within a supplier company.

For instance, if your supplier uses a third-party payment processing tool with weak security, it can result in the exposure of your customers’ payment details. This can lead to financial losses, damage your reputation, and, worst of all, customers may file a lawsuit due to the compromise of their information.

4. Reputational Risk

This risk may arise through a service or supply interruption, supply safety or quality failure, or inefficient supplier’s business practices.

For instance, a supplier you are working with is involved in bribery scandals to cover up labor abuse, which could tarnish your company’s image and lead to huge losses of customer trust.

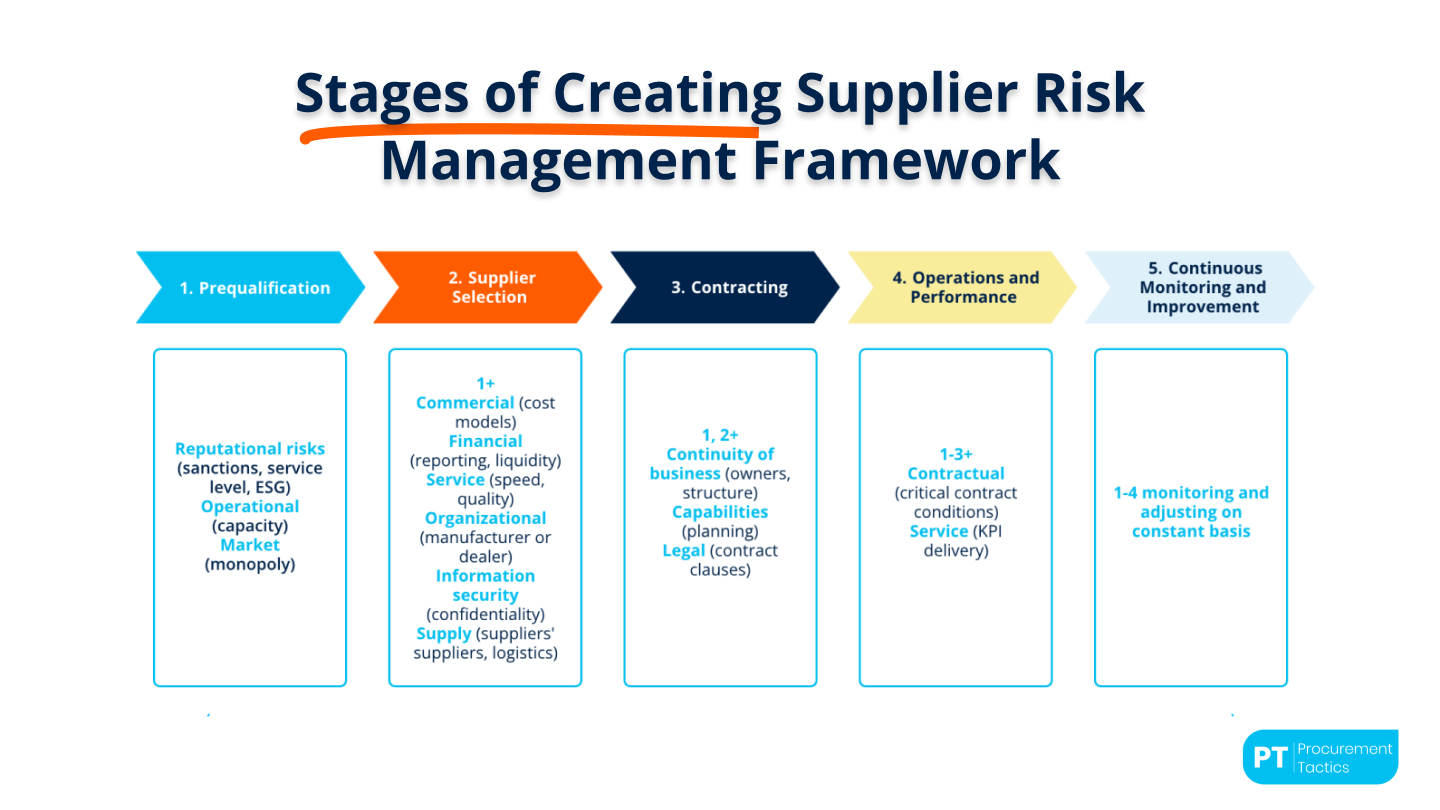

Stages of Creating Supplier Risk Management Framework

The stages that I will show you are the steps you can take to create a robust framework for your business. This is a proven strategy that I have been teaching many procurement professionals across the globe.

1. Prequalification

Before choosing to partner with a supplier, it is better to identify and assess the risks attached to the supplier’s market and environment.

The best practice to do is to make a list of risks related to your industry, category, and environment and perform risk identification for suppliers.

For example, if your supplier pool is located in an area that is at risk of receiving supplies from sanctioned countries due to its geographic location, it is crucial to assess this risk early in the supplier prequalification process.

You can evaluate the risk by including relevant questions in the request for information (RFI) document that is shared with potential suppliers during your supply market assessment.

2. Stage Two is Supplier Selection

In this stage, the best thing to do is to set up a “Gate approach” which allows you to manage specific risks by getting suppliers’ opinions and commitments before they get the chance to have access to the tender documentation.

Most tendering platforms have this feature. As you identified the risks relevant to the supplier at this stage, you can include mitigation elements into the “gate” requirements and share them with suppliers.

For example, you aim to ensure information security. At the “gate” stage, you may ask suppliers to confirm that they have the right controls and mechanisms to safeguard information from the risks of leakage, loss, or damage of customer information.

With this, you can maintain a pool of potential suppliers with fewer information security risks.

3. Contracting

In this stage, numerous risks require careful consideration through contract clauses. However, relying too much on including respective contract clauses may not always help to avoid risks.

Sometimes, you may need to delve into the processes on both your company’s and the supplier’s side to ensure that it suits your business.

For example, if you are entering a supplier contract with a vendor-managed inventory (VMI), you might need to assess both your company and the supplier’s processes. Any gaps you may find can form risk, even if you have relevant clauses in your contract.

4. Operations and Performance

This stage refers to your operational activities, day-to-day communication, and collaboration with the supplier. At this stage, performance management is necessary to minimize risks.

For example, you have a contract for an outsourced workforce. Human rights risks such as unequal treatment, labor abuse, and unfair treatment are quite substantial.

In the key performance indicators (KPIs), the supplier should demonstrate the availability of a management system to control these aspects. Additionally, they should check and report if there are cases of noncompliance.

In practical applications, KPIs can be used to manage grievance mechanisms on the employee side. Monitoring these metrics will help identify and mitigate risks at an earlier stage.

5. Continuous Monitoring and Improvement

If you executed the previous stages successfully, then you should pretty much addressed all the major risks.

However, the environment keeps on changing, leading to new risks arising, or those that were low probability in the past may change profile dramatically. Due to this, you need to have a process in place to monitor the changes in the risk profile of your suppliers so that you can react quickly.

For example, suppliers who have been financially stable for some period may suddenly experience liquidity issues, which we have observed during the Covid-19 pandemic. Thus, early detection and managing this risk will ensure that you still have deliveries coming from this supplier.

Also, it’s crucial to understand that risk monitoring doesn’t stop at utilizing external sources. It’s equally important to communicate and stay connected with your suppliers. Ultimately, your relationship with your supplier is key to effectively managing risks.

Conclusion

Supplier Risk Management Framework is a guideline that identifies and assesses supplier risks at an early stage to help you avoid problems that may arise from those risks.

You may think of the framework as a guide on what you should do before you even encounter the risks that I discussed in this article.

In this article, I shared with you the stages of creating a Supplier Risk Management Framework. In every stage, it’s clear that addressing risks early is more effective than simply reacting to them once they arise.

Furthermore, in mitigating supplier risk, the best practice among the rest is to have close communication with your suppliers. This approach allows you to proactively address potential issues and helps to strengthen your relationships with your current suppliers.

Frequentlyasked questions

What is the supplier risk management framework?

-

Supplier risk management framework is a model that acts as a guideline for businesses to identify and mitigate supplier-related risks in their supply chain.

Why is it important?

-

The framework is important because it gives businesses greater control and helps them get more value by ensuring a more reliable and consistent way to manage supplier risks.

What is the best practice for supplier risk?

-

The best way to manage supplier risk is still through effective supplier relationship management. By maintaining open communication and encouraging collaboration, you can identify and address risks early, while also strengthening your relationships with existing suppliers.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.