Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

How to Do Procurement Benchmarking? Metrics + Template

As taught in the Category Management in Procurement Course / ★★★★★ 4.9 rating

How to Do Procurement Benchmarking?

- Define and gather data on procurement KPIs like cost savings, supplier performance, and cycle times.

- Compare your collected data with industry benchmarks and competitors to pinpoint performance gaps.

- Develop targeted plans based on the benchmarking insights and continuously monitor progress for ongoing optimization.

What is Procurement Benchmarking?

Benchmarking in procurement serves as a data-driven method. It’s a process to demonstrate how procurement adds value to the company. It ensures that practices align with industry standards.

Moreover, it focuses on identifying top-performing organizations. These are groups that excel in various aspects of business. These aspects include capabilities, processes, and performance. It offers opportunities to learn from their successes. Additionally, it sets improvement targets and avoids potential pitfalls. These sound benchmarking practices ultimately contribute to enhancing the organization’s value.

How to Do Procurement Benchmarking?

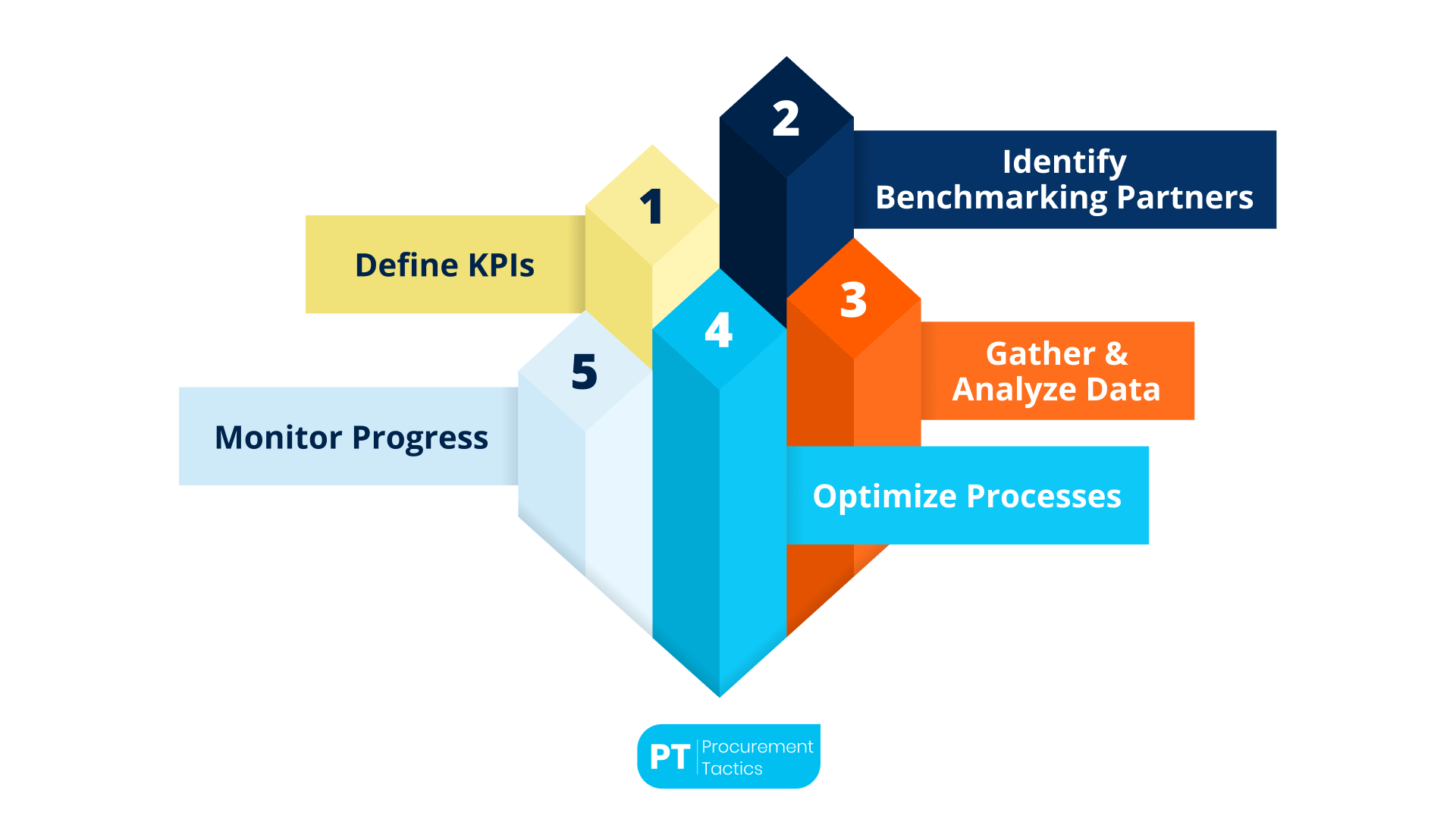

Here’s a step-by-step guide to help you benchmark your procurement effectively:

1. Define Key Performance Indicators (KPIs)

Start by identifying the most relevant and impactful metrics for your procurement operations. Consider what aspects of procurement are critical for your business. This could include KPIs related to cost savings and effective spending management. You can also add on-time delivery and product quality. Any other metrics aligned with your competitive strategy can also work.

Ensure that your chosen KPIs are measurable and specific. It must also be directly tied to your procurement objectives.

Procurement KPIs You Can Benchmark

Procurement benchmarking hinges on the use of precise, measurable performance metrics. Here are 20 essential KPIs designed to drive operational excellence and elevate your procurement function.

1. Cost Savings – Measure the reduction in expenses due to negotiation or process improvements.

2. Cost Avoidance – Track the costs that were prevented through proactive measures.

3. Spend Under Management – Evaluate the percentage of total spend actively managed by procurement.

4. Supplier Performance – Assess overall supplier performance based on quality, reliability, and service.

5. On-Time Delivery – Monitor the percentage of orders delivered within the agreed timeframe.

6. Delivery Quality – Determine the rate at which received products meet predefined quality standards.

7. Procurement Cycle Time – Measure the time taken from purchase requisition to order fulfillment.

8. Purchase Order Accuracy – Evaluate the rate of error-free purchase orders issued.

9. Inventory Turnover – Track how quickly inventory is used and replenished over a period.

10. Contract Compliance – Assess the percentage of spend that complies with contractual agreements.

11. Supplier Lead Time – Monitor the average time suppliers take to deliver orders.

12. Supplier Defect Rate – Measure the percentage of received items that are defective or non-compliant.

13. E-Procurement Adoption Rate – Track the percentage of procurement transactions conducted digitally.

14. Procurement Cost as a Percentage of Spend – Evaluate the efficiency of the procurement function by comparing procurement costs to total spend.

15. Number of Active Suppliers – Monitor the diversity and effectiveness of your supplier base.

16. Supplier Risk Rating – Assess and score suppliers based on potential risks, including financial stability and geopolitical factors.

17. Savings Realization Rate – Compare the planned savings against the actual savings achieved.

18. Supplier Onboarding Time – Measure the time required to onboard new suppliers effectively.

19. Procurement ROI – Calculate the return on investment for procurement activities by comparing savings and performance improvements against procurement costs.

20. Sustainability and Ethical Sourcing Metrics – Evaluate how well suppliers meet sustainability standards and ethical sourcing practices.

2. Identify Benchmarking Partners

Identify organizations within your industry or sector that have similar concerns. These include size, complexity, and procurement practices. These organizations will serve as your benchmarking partners.

Evaluate the procurement metrics and performance of these partners. It can help you gain insights into how they are achieving success. More especially, in areas that are important to your organization.

3. Gather and Analyze Data

Collect data related to the selected KPIs and procurement processes. Data sources can include internal records and industry reports. It also includes surveys, and, if possible, data from your benchmarking partners.

Utilize analytical tools or software to process and analyze the collected data. This analysis should reveal areas where your procurement performance falls short. Be it of your expectations or industry standards.

4. Optimize Processes

Use the insights gained from your data analysis to create improvement plans. These plans can help your procurement processes. Identify areas that need attention. Consider how changes can enhance its performance.

Develop a strategy for addressing shortcomings and fine-tuning your procurement processes. This might involve changes to workflows and supplier relationships. It can also include technology adoption or other aspects of the procurement process.

Collaboration with internal and external stakeholders is a must. Include your procurement team, suppliers, and customers. They are crucial in shaping and implementing the improvement plan. Their insights and feedback can be invaluable.

5. Monitor Progress

Continuously track and monitor your procurement performance over time. Regularly assess the impact of the changes and improvements you’ve implemented.

Be prepared to adjust your plan if significant improvements are not observed. Continuous improvement is an iterative process, and modifications to your strategy may be necessary to achieve desired results.

Importance of Benchmarking

Procurement benchmarking offers organizations a clear and goal perspective on their procurement performance.

This process happens by comparing it to peers or competitors. This external view provides invaluable insights into areas where improvements can be made. Whether it’s enhancing cost efficiency, supplier relationships, or streamlining processes.

Through comparisons, companies can also stay at the forefront of industry trends. It encourages a proactive approach to change. Ultimately, this force drives excellence and competitiveness in procurement practices.

Procurement benchmarking helps organizations optimize spending. It happens by identifying cost-saving opportunities and negotiating better deals with suppliers. This process directly impacts the company’s bottom line. It improves profitability and ensures a healthy financial outlook.

Lastly, benchmarking provides a means for organizations to match their procurement strategies. With broader business objectives, Companies can tackle more. They can assess competition better.

Be it about supplier selection or sustainability initiatives. You can also include risk mitigation strategies. It ensures that procurement becomes a strategic driver of success.

5 Types of Procurement Benchmarking

Different benchmarking types bring value to your organization. These include:

1. Internal benchmarking

Internal benchmarking involves comparing the performance of one part of your organization. You match it against other internal units or subsidiaries. For instance, if you have various companies within a corporate group, you can conduct an evaluation. A subsidiary can test its performance in procurement against another subsidiary.

It can also promote healthy competition within the organization. This process leads to the sharing of best practices and lessons learned. It can also help identify areas of improvement and streamline processes.

The only limitation is that the best practices may exist outside the organization. Also, internal benchmarking may not capture external industry standards or innovations.

2. Competitive benchmarking

Competitive benchmarking involves comparing your organization’s procurement processes. You extend it with those of industry leaders and competitors in the same market. By doing so, you can ensure that your organization remains competitive. Also, it remains aligned with the current market standards.

This type of benchmarking helps organizations understand where they stand with industry peers. It helps them identify areas where they must catch up or outperform competitors.

The primary focus here is on staying competitive and taking cues from the best in the industry.

As a procurement manager at Ahold Delhaize in the FMCG market, I have extensive experience with competitive benchmarking. We conducted this with the help of an external agency (advantagegroup.com).

They conducted a survey in which all retailers evaluated suppliers and vice versa. This allowed us to assess collaboration across various departments. It includes the likes of procurement, category management, logistics, and supply chain management. This approach was very effective. It enabled us to engage in discussions with suppliers. More importantly, about potential areas for improvement in the partnership.

3. Functional benchmarking

Functional benchmarking entails comparing specific functions or departments within your organization. They include procurement or operations management, with world-class leaders in those same functions. Even if they are not direct competitors.

This approach allows organizations to focus on achieving excellence in specific areas. It happens regardless of the industry. It’s beneficial for improving internal processes and achieving operational excellence.

With this type of benchmarking, the scope is narrower. It allows the team to concentrate on specific functions or departments.

4. Generic process benchmarking

Generic process benchmarking is like functional benchmarking. But, it goes one step further by evaluating specific processes rather than entire functions. It allows for a more detailed examination of individual processes and their efficiency. It focuses on individual processes within functions.

This type of benchmarking provides a granular view of processes. It also helps identify areas for improvement. It’s particularly useful when you want to optimize specific processes within your organization.

5. Customer benchmarking

Customer benchmarking assesses your organization’s performance against customer expectations and demands. The primary focus is on aligning services and processes with customer needs.

It helps ensure that your services, including procurement, align with what your customers need and expect.

By understanding and meeting customer expectations, organizations can enhance customer satisfaction and loyalty. This type of benchmarking is particularly relevant in industries with a strong customer focus.

Importantly, organizations can apply multiple benchmarking approaches simultaneously to achieve the best results.

Advantages and Disadvantages of Procurement Benchmarking

It’s important to understand that benchmarking is a valuable tool for organizations. They enhance the company’s procurement processes.

In the following table, we’ll explore the key benefits and potential drawbacks. It can help you make informed decisions. Ultimately, it provides leverage for your organization.

Best Practices in Procurement Benchmarking

It wouldn’t be honest to say that one-size-fits-all when it comes to sourcing and procurement benchmarks. However, following best practices can help any organization. It’s for figuring out its unique needs and creating a benchmarking process to meet them.

Here’s what you can do:

1. Start with a plan

To make the most of your procurement benchmarks, you need a plan to:

- Identify the benchmarks that matter most for your procurement performance, efficiency, and competitiveness.

- Set up these benchmarks and create a plan to track them effectively.

- Get the digital tools needed to analyze performance, spending, and compliance data for actionable insights.

Your procurement team can craft this plan by answering these basic questions:

- Which benchmarks related to your current workflows are most important?

- Should you create new benchmarks to measure the impact of new processes?

- What benchmarks are most valuable for your stakeholders, and should they be customized?

- How many benchmarks should you have – not too few, not too many?

- How specific should each benchmark be to provide useful insights?

- What data sources and tools will you use for analysis?

- How will you integrate benchmarking into your overall business processes?

- What methods will you use to evaluate the effectiveness of best practices?

- How can you keep the costs of benchmarking low?

- What processes need updating to apply insights from benchmarking for improvement?

2. Align your benchmarking to your business goals

Procurement benchmarking is more than just about making procurement better; it’s part of a larger effort to boost overall business performance and profits. How do you incorporate your goals within your benchmarking?

- Work with your finance team to ensure your benchmarks fit with your financial goals, such as Return on Investment Capital (ROIC) or Economic Value Added (EVA).

- Take advantage of existing benchmarks in your industry. Organizations like the American Productivity & Quality Center (APQC) offer benchmarks for various sectors.

- Calculate the overall efficiency of your procurement by considering cost savings and financial benefits compared to the annual procurement cost.

- Link your benchmarks to your enterprise’s value creation by tracking spending, supply chain performance, and data efficiency. This helps in understanding how procurement affects cash flow and profit.

- Assess efficiency in processes and how well stakeholder needs are met using benchmarks like approval time and error rates.

3. Invest in procurement technology

Having a plan and knowing what to measure is just the start. To get the most value from your procurement benchmarks, you need the right digital tools. Manual processes won’t cut it in today’s data-rich procurement landscape.

How can businesses benefit from procurement technology?

- All your data, from spending to trends, is stored in one user-friendly, cloud-based platform. This brings transparency, accuracy, and real-time access for monitoring KPIs and spotting opportunities or issues.

- Ditching paper processes saves money and resources. It ensures that all spending data is collected electronically for analysis.

- Robots handle repetitive tasks quickly and with high accuracy, reducing errors and delays. This, combined with data management, provides clean data for better analysis and insights.

- Data is at the heart of process management. It makes it easier to set, monitor, and adjust benchmarks, leading to more savings and less waste.

- Easily expand benchmarks across your organization, including new projects and departments, while keeping all your data integrated.

- Connect diverse data sources, both internal and external, to highlight where you’re creating value and areas where you can improve efficiency and reduce risks.

Conclusion

Making smart business decisions and strategic sourcing are crucial. So as driving growth and innovation develop business intelligence efficiently. Don’t hesitate to harness the valuable insights. Those that come from setting up and tracking the sourcing and procurement benchmarks. These are most relevant to your company’s growth, performance, and financial success.

I have created a free-to-download editable procurement benchmarking template. It’s a PowerPoint file you can use to analyze the effectiveness of the different processes in your procurement. I even created a video where I’ll explain how you can use this template.

Frequentlyasked questions

What are the types of benchmarking in procurement?

There are five primary types of benchmarking in procurement. Internal benchmarking involves comparing one part of an organization with others within the same organization. Competitive benchmarking looks at industry leaders operating in the same market. Functional benchmarking focuses on achieving excellence in specific areas, while generic process benchmarking evaluates individual processes for improvement. Customer benchmarking assesses an organization’s performance against customer expectations.

What is benchmarking in procurement and supply chain management?

Benchmarking in procurement and supply chain management is the process of comparing an organization’s practices and performance with those of industry peers or best-in-class companies to identify areas for improvement and enhance efficiency, cost-effectiveness, and overall effectiveness in procurement and supply chain operations.

How is benchmarking used to measure purchasing performance?

Benchmarking measures purchasing performance by comparing an organization’s procurement practices, costs, and efficiency with those of top-performing competitors or industry leaders to identify areas for improvement and best practices to adopt.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.

Popular Procurement Courses

At Procurement Tactics, we educate Procurement Professionals to close better deals, secure supply and advance their career. Our courses are online and self-paced.

Negotiation Course for Procurement

Learn from industry experts who negotiated billion $ deals

Artificial Intelligence in Procurement Course

Unleash the power of artificial intelligence within procurement

AI Implementation Course for Procurement Leaders

Lead the AI shift with confidence in procurement

Related Articles

Human-AI Balance in Procurement — Striking A Balance

Written by Marijn Overvest | Reviewed by Sjoed Goedhart | Fact Checked by Ruud Emonds | Our editorial policyHuman-AI Balance in Procurement — Striking A BalanceAs taught in the Artificial Intelligence in Procurement Course / ★★★★★ 4.9 ratingTable of contents AI in...

Generative AI in Procurement — 5 Use Cases + 10 Emerging Trends

Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policyGenerative AI in Procurement — 5 Use Cases + 10 Emerging TrendsAs taught in the Artificial Intelligence in Procurement Course / ★★★★★ 4.9 ratingTable of...

Managing Gen Z Talent: Future-Proofing Procurement Teams

Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policyManaging Gen Z Talent: Future-Proofing Procurement TeamsAs taught in the Gen Z & Generational Management in Procurement / ★★★★★ 4.9 ratingTable of contents...