Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

Procurement Dashboard — Explained + Example

What is a procurement dashboard?

- A procurement dashboard is a visual reporting tool used to monitor, track, and analyze key procurement metrics in real-time.

- The procurement dashboards streamline data tracking for effective procurement management and decision-making.

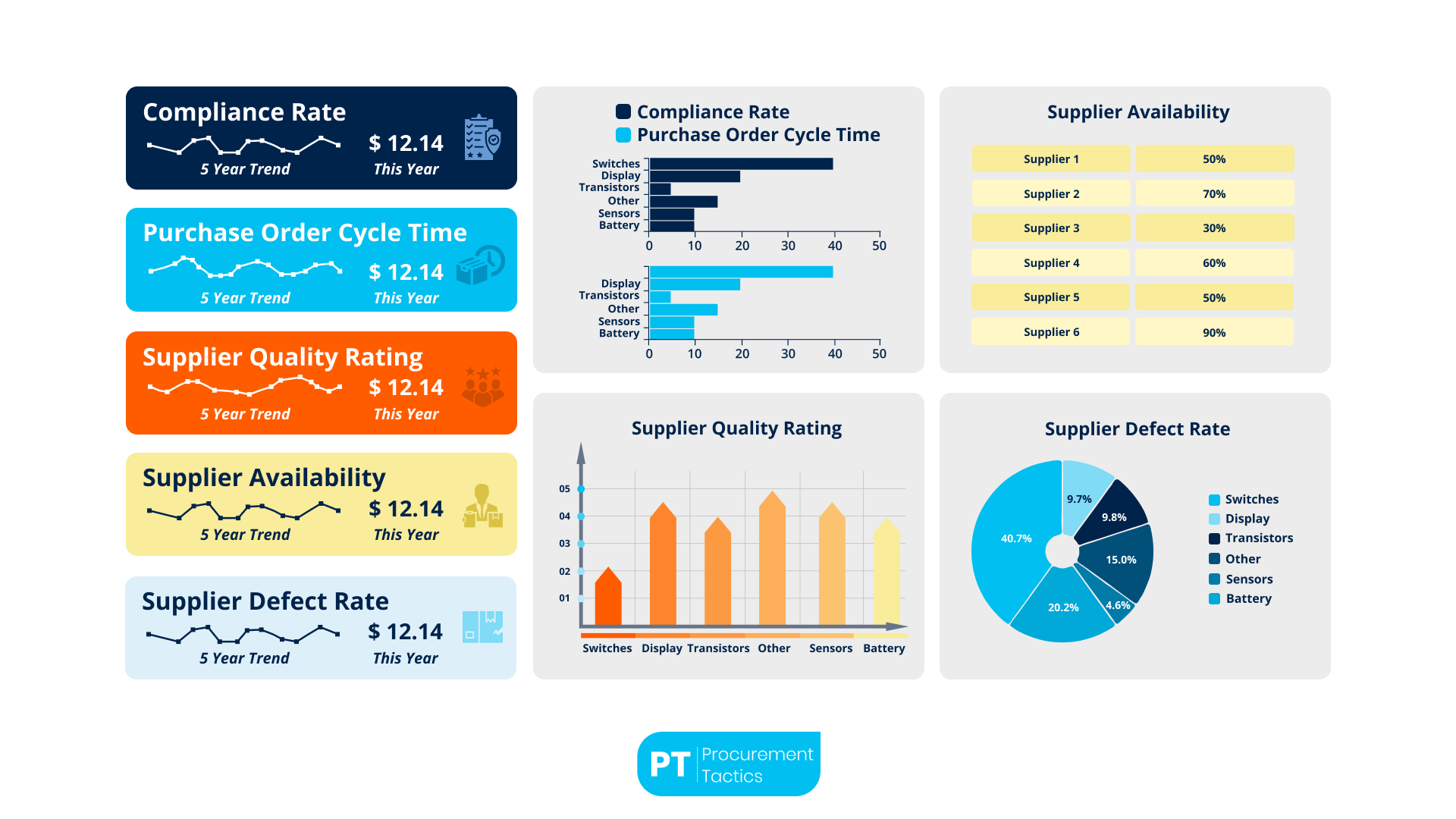

- Key Performance Indicators (KPIs) in procurement dashboards include Compliance Rate and Purchase Order Cycle Time.

What is a Procurement Dashboard?

A procurement dashboard is a visual reporting tool used to monitor, track, and analyze key procurement metrics in real-time. It pulls data from procurement systems and displays it in a user-friendly format, typically using charts, tables, and graphs.

These dashboards are essential for procurement teams who deal with large volumes of data—bills, contracts, invoices, and more. Without a dashboard, tracking all this information manually can be overwhelming and error-prone. That’s why modern procurement systems often store this data in centralized databases or cloud platforms.

The dashboard then acts like a control panel, giving procurement managers instant visibility into the health of the procurement process, similar to how a car’s dashboard shows speed, fuel levels, and engine status. Instead of digging through files or spreadsheets, users can quickly spot delays, cost overruns, or compliance issues and take corrective action.

Procurement dashboards not only save time but also support better decision-making and promote transparency across the organization.

Procurement KPIs You Should Include in Your Dashboards

In most procurement dashboards, KPIs are a must in order to establish the type of information one wants to get from the procurement dashboard. With the help of these KPIs, the company’s procurement department can start working on what to improve when they start creating a procurement plan for the company.

These KPIs are often taken for granted, but we at Procurement Tactics believe that these KPIs are very important to take note of. These KPIs will determine exactly what the procurement team needs when they start the procurement process.

Each of these KPIs is but a small fraction of what the Negotiation Gamechanger can teach you. Our classes are made to help the modern procurement manager in taking charge of a world where procurement means everything for a company’s growth and survival.

So without further ado, it’s time to take a look at the five important KPIs needed for procurement dashboards:

1. Compliance Rate

This is a procurement KPI that is crucial when it comes to determining the final quality of a product. It measures the percentage of products received from suppliers that do not meet the compliance specifications and quality requirements.

The supplier defect rate is more critical in some industries that have high-risks and multi-tiered supplier bases like the aerospace and defense or the automotive.

Tracking your different suppliers’ defect rates and breaking them down into defect types will provide you insights on which supplier is more performant and reliable than others, and what type of errors are done.

2. Purchase Order Cycle Time

The purchase order cycle time is a procurement KPI that covers the end-to-end ordering process, from the moment a purchase order is created to the order approval, receipt, invoice, and finally payment of the order.

It focuses on the order and does not include the creation and delivery of the product or material itself.

3. Supplier Quality Rating

The quality rating is one of the supplier performance metrics critical in evaluating present as well future relationships with suppliers. If the designated supplier continuously delivers a lower quality score, then their status may be downgraded, or corrective measures implemented until issues in the supply chain are resolved.

For example, if the supplier availability was low, and you cannot rely on their stock, your business can, consequently, suffer due to a lack of products. Therefore, it’s only important that a potential supplier should have a great supplier quality rating in accordance with your company’s procurement dashboard.

4. Supplier Availability

Supplier availability is a procurement KPI that refers to the number of times goods were available on the supplier’s side, or to the number of orders placed with the supplier.

In an era of fast-changing consumer habits, where the lines between different channels are blurred, and where mobile-commerce, online purchases, in-store consumer-specific marketing all merge in one retail experience, it is important to manage suppliers as efficiently as possible to guarantee the availability of stocks.

By monitoring the evolution of your supplier’s availability of stocks, you know the degree of reliability you can place in them.

5. Supplier Defect Rate

This is a procurement KPI that is crucial when it comes to determining the final quality of a product. It measures the percentage of products received from suppliers that do not meet the compliance specifications and quality requirements.

The supplier defect rate is more critical in some industries that have high-risks and multi-tiered supplier bases like the aerospace and defense or the automotive.

Tracking your different suppliers’ defect rates and breaking them down into defect types will provide you insights on which supplier is more performant and reliable than others, and what type of errors are done.

Conclusion

In essence, a procurement dashboard stands as a pivotal instrument for companies immersed in constant procurement activities. It helps procurement teams to make informed decisions, ensure supplier performance, and maintain process efficiency.

By integrating key procurement KPIs like compliance rate, purchase order cycle time, and supplier defect rate, organizations gain deeper insights into their operations and can proactively address issues before they escalate.

With the right metrics in place, a well-designed procurement dashboard becomes a powerful driver for cost savings, quality control, and long-term supplier relationships.

Frequentlyasked questions

What is a procurement dashboard?

A procurement dashboard is a part of a procurement system where various information regarding a company’s procurement process can be seen.

What makes the procurement dashboard?

Most of the time, the procurement dashboard is created by the automated procurement system itself after calculating all sourcing processes.

Who is in charge of the procurement dashboard?

The procurement manager or procurement head is the one who checks the procurement dashboard at all times.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.