Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

8 Supplier Performance Management KPIs for 2026

As taught in the Supplier Relationship Management Course / ★★★★★ 4.9 rating

What are supplier performance management KPIs?

- Supplier performance management KPIs are quantitative metrics used to track and evaluate a supplier’s performance against predefined objectives and benchmarks.

- These KPIs help align suppliers with business goals, set clear expectations, and facilitate performance feedback.

- There is no one-size-fits-all approach to selecting KPIs for supplier performance management; they should be tailored to specific business needs.

Procurement KPIs

Procurement KPIs are key metrics used to measure the efficiency and effectiveness of the procurement process within an organization. They help track costs, quality, speed, and supplier reliability, enabling better strategic decision-making and supply chain optimization.

The most important procurement KPIs include total procurement costs, procurement cycle time, supplier delivery accuracy and quality, and cost savings achieved in procurement. Analyzing these metrics helps identify inefficiencies, improve supplier relationships, and enhance overall operational performance.

Well-defined and consistently monitored KPIs help companies reduce risks, control costs, and ensure business continuity through a stable and efficient procurement process.

What are Supplier Performance Management KPIs?

To develop strategic relations, reduce costs, and improve the quality of your procurement process, here are a number of useful Supplier Key Performance Indicators:

1. Leadtime

The lead time is between placing an order and having it delivered. Your business procedures may be delayed if orders are not filled promptly, which may lead to the loss of clients who are used to quick turnarounds in today’s fast-paced society. Operational improvements brought about by reducing delivery lead times can hasten order fulfillment and boost customer satisfaction.

Metric: The average number of days it takes a supplier to deliver the goods after an order is placed.

2. Defect Rates

The requested goods or services must always adhere to the quality standards stipulated in your contract or the purchase order. Receiving inferior products or materials can put companies at risk, affecting stock levels or necessitating the expenditure of time and resources to correct the order. Businesses can determine whether suppliers routinely supply products or services that fall short of the required quality standards by monitoring each supplier’s defect rate.

Metric: Divide the total number of orders by the number of orders that contain damaged goods.

3. Compliance

Supplier relationships are strengthened when they abide by the agreements and rules of your business. You can learn more about how effectively a supplier meets the agreed-upon business needs by monitoring the compliance rate. Delivery time, lead time, discounts, turnaround time for delays, and payment arrangements are taken into account.

Metric: Depending on the specifics of the contract, many indicators can be used to assess compliance.

4. Customer Service

Procurement professionals have the chance to evaluate the complete experience of dealing with a supplier using this KPI. Was the level of customer service satisfactory? Were issues and complaints handled effectively and professionally, and was it simple to get in touch with them? Do you deal with a single person or a number of persons within that organization?

Metric: The number of disputes which are separated by the number of orders issued.

5. Risk and Transparency

This KPI assesses the supplier’s capacity to control and reduce operational risks, including those related to geopolitics, supply chain disruptions, and natural disasters.

Metric: Depending on the types of risk being considered, a range of measures can be used to evaluate supplier risk.

6. On-time delivery

It’s critical to provide goods and services on time if you want to keep customers happy and loyal. You can evaluate the supplier’s adherence to the specified delivery dates using this KPI.

Metric: Divide the number of deliveries made on the agreed deadline by the total number of their deliveries, multiplied by 100. As a result, you get the percentage of products delivered on time.

7. Order Accuracy

Order accuracy measures how precisely providers fulfill your orders, or, put another way, how frequently items are delivered incorrectly. Your business operations may be considerably slowed down if an order contains the wrong goods or the wrong quantities of the right items.

Metric: The number of orders that were delivered accurately to 100%, divided by the total number of orders.

8. Return on investment

This is an opportunity to compare the cost reductions you achieved by working with that provider to your overall budget.

Metric: Procurement cost savings divided by costs is the usual way to measure this KPI. However, it still depends on your organization’s approach.

Pro Tip: Tracking KPIs is just the first step—turning those metrics into stronger supplier relationships is where the real value lies. The smartest procurement teams use KPI insights not just to evaluate performance, but to open conversations, align expectations, and foster long-term collaboration.

⭢ If you want to elevate your supplier performance management strategy beyond the numbers, our Supplier Relationship Management Course will guide you in transforming data into trust, transparency, and true partnership.

What is Supplier Performance Management?

Supplier Performance Management (SPM) is a business practice that involves actively monitoring, measuring, and managing the performance of a company’s suppliers to ensure they meet the required quality, cost, delivery, and other performance expectations. As performance by suppliers can directly affect the overall efficiency, quality of products, and customer satisfaction of an organization, SPM is an important part of procurement and supply chain management.

Managing and optimizing supplier performance is both critical and challenging. It’s not all about the price. You may receive invoices from suppliers following the agreed price, but unless a service or product meets your expectations it is unlikely that you can achieve this savings target. That’s why setting metrics or Key Performance indicators will help smoothen Supplier Performance Management.

Additionally, regular supplier performance evaluations can assist you in spotting possible supply chain and procurement risks early on so that they can be fixed before they become serious issues. SPM can assist in ensuring that your goods and services adhere to the highest standards of quality. SPM can also help you prepare a contingency plan in case of disruption, for example, if the main supplier were to go out of business.

How Do You Choose KPIs for Supplier Performance Management?

While we provided some of the most useful KPIs, it still depends on the organization. There is no one-size-fits-all method for selecting KPIs for supplier evaluation because different suppliers may have various roles and responsibilities within your supply chain.

There are, however, some broad guidelines and procedures that you can follow. Establish your supplier evaluation criteria and objectives first, together with the crucial success elements and hazards associated with each. Then, choose, validate, and rank the KPIs that capture the important success factors and hazards. Think about the KPIs’ applicability, accuracy, measurement simplicity, significance, and impact.

Finally, choose the number of KPIs you require to have a thorough and accurate understanding of your supplier performance.

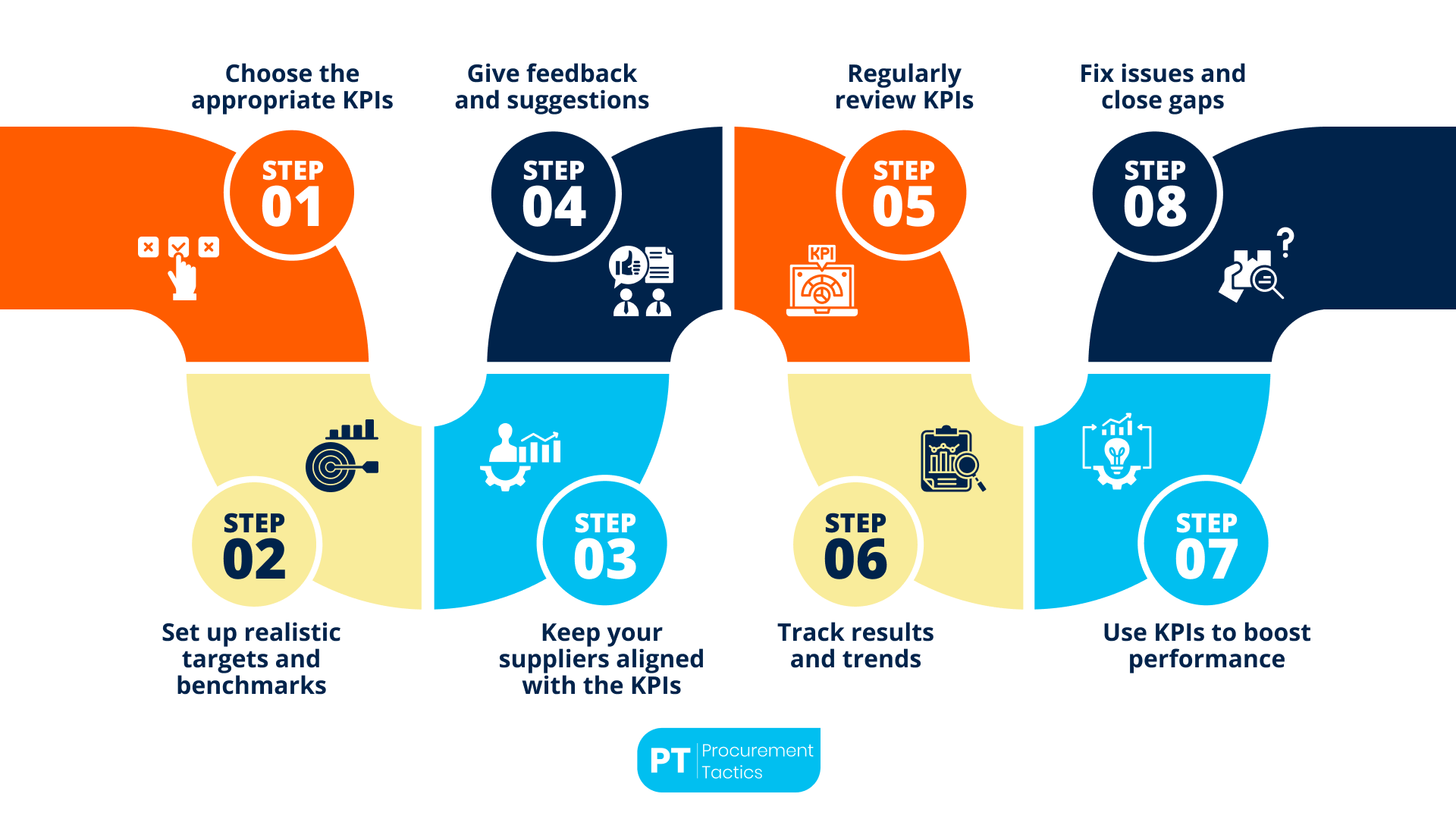

Evaluation Suppliers with KPIs Process

The first step in evaluating your suppliers is to choose the appropriate KPIs. You must set up precise and realistic targets and benchmarks for each KPI in order to properly monitor and enhance your supplier performance and relationship. It’s crucial to keep your suppliers informed, align the KPIs with them, and provide them with regular praise and constructive criticism.

Additionally, you should routinely and routinely assess and evaluate the KPIs, track and report the KPIs’ outcomes and analyze and interpret the KPIs’ patterns and trends. You may then utilize the KPIs to motivate ongoing innovation and performance improvement by identifying and addressing any gaps and problems in your supplier’s performance and relationship.

Conclusion

Assessing supplier performance is a necessary step in improving your company’s buying potential. Your team will have more data-driven insights than ever before thanks to these KPIs. You will be able to add new value to your company while also monitoring progress, reducing costs, and boosting profitability as a result of tracking supplier KPIs.

The process of putting new contracts into effect can seem unpredictable and dangerous. Naturally, you could feel pressured to monitor your supplier KPIs carefully. But as time passes, it becomes simpler to get complacent. Overall, you’re now poised to have a dramatic impact on your company’s performance.

But before you proceed to read the whole article, I have created a free-to-download editable procurement benchmarking template. It’s a PowerPoint file you can use to analyze the effectiveness of the different processes in your procurement. I even created a video where I’ll explain how you can use this template.

Frequentlyasked questions

What is Supplier Performance Management?

Supplier Performance Management (SPM) is a business practice that involves actively monitoring, measuring, and managing the performance of a company’s suppliers to ensure they meet the required quality, cost, delivery, and other performance expectations.

What is Supplier Performance Management KPIs?

KPIs are quantitative measurements that track and assess a supplier’s performance in relation to predetermined objectives and benchmarks. They can be used to gauge a supplier’s performance in a number of areas, including delivery, quality, cost, innovation, and compliance.

How do you choose KPIs for Supplier Performance Management?

There is no one-size-fits-all method for selecting KPIs for supplier evaluation because different suppliers may have various roles and responsibilities within your supply chain. There are, however, some broad guidelines and procedures that you can follow.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.